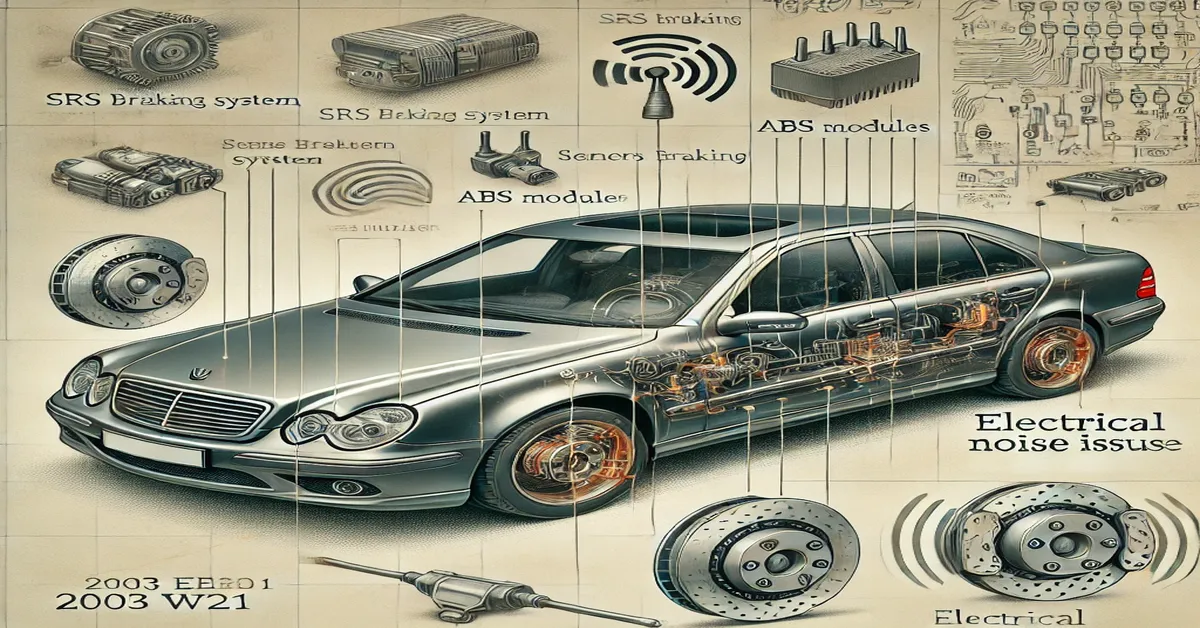

The 2003 Mercedes-Benz E500 W211 is a luxury sedan known for its advanced technology and driving comfort. One of its standout features is the Sensotronic Brake Control (SBC) system, a highly sophisticated braking system that enhances safety and performance. However, 2003v e500 w211 srs braking system making constant electrical noise as vehicles age, issues may arise, and one commonly reported problem with this model is constant electrical noise emanating from the SRS (Supplemental Restraint System) braking system.

This article delves into the specifics of the 2003 E500 W211’s braking system, the potential causes of electrical noise, 2003v e500 w211 srs braking system making constant electrical noise troubleshooting methods, and preventive measures. By understanding the intricacies of the system and the steps needed to address such issues, owners can maintain the reliability and safety of their vehicle.

Overview of the SRS Braking System

The SRS braking system in the 2003 Mercedes-Benz E500 W211 is closely tied to the Sensotronic Brake Control (SBC). The SBC system is a by-wire braking system, meaning it relies heavily on electronic components to modulate braking force. Unlike traditional hydraulic systems, the SBC uses sensors, actuators, and processors to enhance braking precision.

Key Features of the SBC System:

- Electro-hydraulic Actuation: The SBC uses an electric motor to generate hydraulic pressure, replacing the traditional brake booster.

- Brake-by-Wire Technology: Commands from the brake pedal are transmitted electronically to the braking system.

- Adaptive Braking: The system adjusts braking force based on driving conditions, enhancing stability and safety.

- Emergency Features: The SBC system incorporates emergency braking functions, ensuring optimal stopping power during critical situations.

While these features provide superior braking performance, they also introduce complexity, making the system prone to specific issues, particularly as the vehicle ages.

Common Causes of Electrical Noise in the SRS Braking System

Electrical noise in the SRS braking system can result from various factors, including wear and tear, electrical component failures, and system malfunctions. Below are some common causes:

1. SBC Pump Motor Noise

The SBC braking system relies on a high-pressure pump motor to generate and maintain hydraulic pressure. Over time, the motor may wear out, leading to constant electrical noise. This noise is often a result of:

- Bearing Wear: Worn-out bearings can produce a whining or humming sound.

- Overworking: If the system detects a drop in hydraulic pressure, the pump motor may run continuously, causing excessive noise.

2. Sensor Malfunctions

The SBC system uses various sensors to monitor and regulate braking performance. A faulty sensor can send incorrect signals, leading to erratic system behavior and electrical noise. Common culprits include:

- Brake pressure sensors.

- Wheel speed sensors.

- Pedal position sensors.

3. Faulty SBC Unit

The SBC control unit processes inputs from sensors and controls the braking system. A malfunctioning unit may generate electrical noise or cause the pump motor to run unnecessarily.

4. Electrical Wiring Issues

Aging or damaged wiring can cause electrical interference and noise. Corroded connectors, loose wiring, or short circuits may disrupt the system’s functionality and produce audible electrical sounds.

5. Software Glitches

Outdated or corrupted software in the SBC control module can cause the system to behave abnormally, potentially leading to constant noise.

6. Brake Pad Wear

While not directly related to electrical components, excessively worn brake pads can cause the system to compensate for reduced braking efficiency, overworking the pump motor.

Diagnosing Electrical Noise in the SRS Braking System

Identifying the root cause of electrical noise in the SRS braking system requires a systematic approach. Below are diagnostic steps to isolate and address the issue:

1. Visual Inspection

Begin by inspecting the braking system for visible signs of wear or damage:

- Check for worn brake pads or discs.

- Inspect wiring and connectors for corrosion or damage.

- Look for fluid leaks around the SBC unit or brake lines.

2. Listen to the Noise

Pay close attention to the characteristics of the noise:

- Whining or Humming: Likely from the SBC pump motor.

- Clicking: May indicate relay or actuator issues.

- Buzzing: Could be caused by electrical interference or a faulty component.

3. Scan for Diagnostic Trouble Codes (DTCs)

Using an OBD-II scanner or Mercedes STAR diagnostic tool, check for stored error codes in the SBC system. Common codes related to electrical noise include:

- C249F (Service Threshold Reached): Indicates the SBC unit is nearing the end of its service life.

- C26xx (Sensor Errors): Points to sensor malfunctions.

4. Test the SBC Pump Motor

Monitor the pump motor’s operation using diagnostic tools. If it runs continuously or struggles to maintain pressure, it may need replacement.

5. Evaluate the Control Module

Examine the SBC control module for software glitches or hardware failures. Updating the software or replacing the module may resolve the issue.

Repair and Maintenance Solutions

Once the root cause is identified, the appropriate repair or maintenance steps can be taken. Below are common solutions for resolving electrical noise in the SRS braking system:

1. Replace the SBC Pump Motor

If the pump motor is worn out or overworking, replacing it is the most effective solution. Ensure the replacement part is compatible with the 2003 E500 W211.

2. Address Sensor Issues

Replace faulty sensors and recalibrate the system using diagnostic tools. This ensures accurate inputs for optimal system performance.

3. Repair Wiring and Connectors

Fix damaged wiring, clean corroded connectors, and ensure all electrical connections are secure.

4. Update the SBC Control Module Software

Check for software updates from Mercedes-Benz and apply them using a compatible diagnostic tool.

5. Replace the SBC Unit

If the SBC unit has reached its service threshold or is malfunctioning, replacing it may be necessary. Mercedes recommends replacing the unit every 10 years or 300,000 braking cycles.

6. Maintain the Braking System

Regular maintenance, including brake pad and fluid replacement, helps prevent excessive wear on the SBC components.

Preventive Measures

Preventing electrical noise in the SRS braking system involves regular maintenance and proactive care:

1. Schedule Routine Inspections

Regularly inspect the braking system for signs of wear, leaks, or damage.

2. Replace Brake Fluid

Change the brake fluid as per the manufacturer’s recommendations to maintain optimal hydraulic performance.

3. Monitor Brake Pad Wear

Replace brake pads before they become excessively worn to prevent undue stress on the system.

4. Update Software

Keep the SBC control module’s software up-to-date to ensure smooth operation.

5. Use Quality Components

When replacing parts, use genuine or high-quality aftermarket components to ensure compatibility and durability.

When to Seek Professional Help

While some maintenance tasks can be performed by skilled DIY enthusiasts, complex issues with the SBC system often require 2003v e500 w211 srs braking system making constant electrical noise professional expertise. Seek help from a qualified mechanic or Mercedes-Benz specialist if:

- Electrical noise persists despite basic troubleshooting.

- Diagnostic tools reveal multiple error codes.

- The SBC unit or pump motor needs replacement.

Conclusion

The 2003 Mercedes-Benz E500 W211’s SRS braking system is a marvel of engineering, offering advanced safety and performance features. However, as with any complex system, issues like constant electrical noise can arise due to aging components or malfunctions. Understanding the workings of the SBC system, diagnosing problems systematically, and implementing effective solutions can help restore its reliability.

By maintaining the braking system through regular inspections and timely replacements, owners can extend the life of their vehicle while ensuring a smooth and safe driving experience.

FAQs

1. Why is my 2003 E500 W211’s SRS braking system making electrical noise?

The noise may result from a worn-out SBC pump motor, faulty sensors, damaged wiring, or outdated control module software.

2. How can I diagnose the source of the noise in the braking system?

Start with a visual inspection, listen to the noise characteristics, and use diagnostic tools to scan for error codes in the SBC system.

3. Is it safe to drive with constant electrical noise in the braking system?

While the vehicle may still be operable, electrical noise often indicates underlying issues that could affect braking performance. Address the problem promptly to ensure safety.

4. How often should the SBC unit be replaced?

Mercedes-Benz recommends replacing the SBC unit every 10 years or 300,000 braking cycles, whichever comes first, to maintain system reliability.

5. Can I fix the electrical noise issue myself, or do I need professional help?

Some tasks, like inspecting wiring or updating software, can be done by experienced DIY enthusiasts. However, complex repairs, such as replacing the SBC unit, should be handled by a professional.

6. How can I prevent issues with the SRS braking system in the future?

Regular maintenance, including brake fluid changes, brake pad replacement, and system inspections, can help prevent problems and prolong the system’s life.