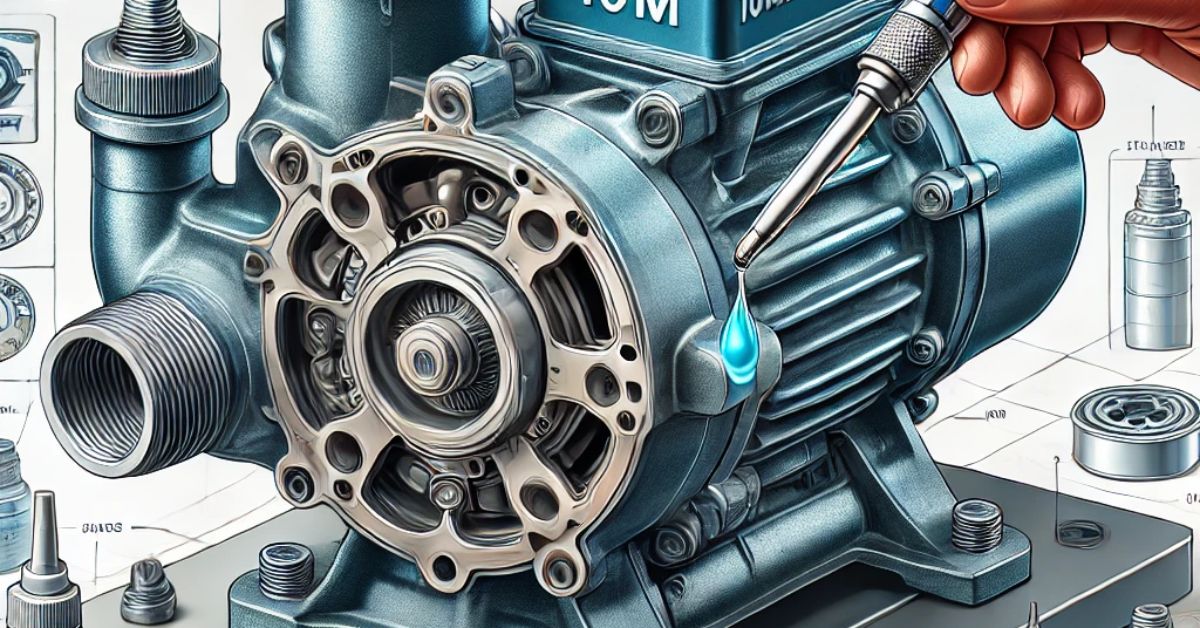

The Pedrollo JSWm 10M pump is a highly regarded model in the world of water pumps, known for its robust build, efficient performance, and longevity. Like all mechanical devices, proper maintenance is key to ensuring that the pump continues to perform optimally over its lifespan. One crucial aspect greasing pedrollo jswm 10m pump of maintenance is greasing, which minimizes friction, reduces wear and tear, and protects the pump’s moving parts from corrosion and damage.

In this article, we will explore the nuances of greasing the Pedrollo JSWm 10M pump, detailing the steps, benefits, and tools required for this essential maintenance task. Additionally, we will discuss how to identify when greasing is needed, tips for prolonging the pump’s life, and safety precautions to consider during maintenance.

Understanding the Pedrollo JSWm 10M Pump

Before diving into the greasing process, it’s important to understand the pump’s structure and operation. The Pedrollo JSWm 10M is a self-priming jet pump, commonly used for water supply in domestic, agricultural, and industrial settings. Its compact design, reliability, and capacity to handle small amounts of sand in the water make it an excellent choice for various applications.

The pump consists of several key components:

- Motor: The electric motor powers the pump and drives the impeller.

- Impeller: A rotating component that moves water by converting rotational energy into kinetic energy.

- Seals and Bearings: These reduce friction and support the motor and impeller shafts.

- Casing: The external body that houses the internal components.

Regular lubrication, particularly of the bearings, ensures smooth operation and prevents premature failure.

Importance of Greasing

Greasing the Pedrollo JSWm 10M pump has several benefits:

- Reduces Friction: Lubrication minimizes the resistance between moving parts, reducing energy loss and wear.

- Prevents Overheating: Proper lubrication dissipates heat generated by friction, preventing damage.

- Extends Lifespan: Regular greasing can significantly increase the operational life of the pump.

- Prevents Corrosion: Grease acts as a protective barrier, shielding metal parts from moisture and rust.

Neglecting lubrication can lead to several issues, such as increased noise, reduced efficiency, and even mechanical failure.

Tools and Materials Needed

To grease the Pedrollo JSWm 10M pump, you’ll need the following:

- High-quality, manufacturer-recommended grease (usually lithium-based or water-resistant)

- A grease gun for precise application

- A clean cloth or rag

- Screwdrivers or wrenches (to access internal components)

- Safety gloves and goggles

Ensure that you use the grease specified by the manufacturer to avoid compatibility issues that could damage the pump.

Step-by-Step Guide to Greasing the Pump

1. Preparation

- Turn Off the Pump: Disconnect the power supply to ensure safety.

- Clean the Pump Exterior: Wipe down the external casing to remove dust, dirt, and debris. This prevents contaminants from entering the internal components.

2. Access the Bearings

- Locate the Bearings: Bearings are usually situated near the motor and impeller shafts.

- Remove Protective Covers: Using a screwdriver or wrench, carefully remove any protective covers or panels that shield the bearings.

3. Inspect the Bearings

- Check for Wear: Inspect the bearings for signs of damage, such as cracks or excessive wear.

- Clean the Bearings: If old grease or debris is present, remove it using a clean cloth.

4. Apply Grease

- Load the Grease Gun: Fill the grease gun with the appropriate lubricant.

- Apply Grease: Inject grease into the bearing housing through the designated grease fittings. Be careful not to over-grease, as this can cause pressure buildup and damage seals.

5. Reassemble the Pump

- Replace Covers: Once greasing is complete, securely reattach the protective covers.

- Clean the Area: Wipe away any excess grease to maintain cleanliness.

6. Test the Pump

- Reconnect Power: Turn the power supply back on and run the pump.

- Monitor Performance: Listen for unusual noises and ensure smooth operation.

When to Grease the Pump

The frequency of greasing depends on factors such as usage intensity, environmental conditions, and the type of water being pumped. As a general rule:

- Moderate Use: Grease the pump every six months.

- Heavy Use or Harsh Conditions: Grease the pump every three months.

Always refer to the manufacturer’s guidelines for specific recommendations.

Common Mistakes to Avoid

- Over-Greasing: Excess grease can damage seals and attract dirt, leading to premature wear.

- Using the Wrong Grease: Incompatible grease can degrade bearings and reduce efficiency.

- Ignoring Maintenance Schedules: Irregular maintenance increases the risk of mechanical failure.

- Skipping Inspection: Failing to inspect components before greasing may overlook underlying issues.

Tips for Prolonging Pump Life

- Regular Maintenance: Follow a consistent schedule for cleaning, greasing, and inspecting the pump.

- Monitor Noise Levels: Unusual noises often indicate a need for lubrication or repairs.

- Protect Against Moisture: Ensure the pump is installed in a dry, well-ventilated area to prevent rust.

- Replace Worn Parts: Address wear and tear promptly to avoid further damage.

Safety Precautions

- Disconnect Power: Always turn off the pump and disconnect it from the power supply before maintenance.

- Use Safety Gear: Wear gloves and goggles to protect against grease and debris.

- Handle Tools Safely: Use tools carefully to avoid injury or damage to the pump.

- Dispose of Waste Properly: Dispose of old grease and cleaning materials in accordance with local regulations.

Conclusion

Greasing the Pedrollo JSWm 10M pump is a straightforward but essential maintenance task that ensures its longevity and optimal performance. By following the steps outlined in this guide, you can keep your pump in excellent working condition and avoid costly repairs or replacements.

FAQs

1. How often should I grease my Pedrollo JSWm 10M pump?

The frequency of greasing depends on usage and environmental conditions. For moderate use, grease every six months. In harsh or heavy-use conditions, grease every three months.

2. What type of grease should I use for the Pedrollo JSWm 10M pump?

Use high-quality, water-resistant grease recommended by the manufacturer. Check the user manual for specific product recommendations.

3. What happens if I over-grease the pump?

Over-greasing can cause pressure buildup, damage seals, and attract dirt, leading to premature wear and reduced efficiency.

4. How can I tell if my pump needs greasing?

Signs include increased noise, reduced efficiency, overheating, or visible wear on the bearings.

5. Can I grease the pump while it is running?

No, always disconnect the power supply and turn off the pump before performing maintenance to ensure safety.

6. What should I do if I notice damage during greasing?

If you observe damaged bearings or other components, replace them immediately or consult a professional for repairs to prevent further issues.