Introduction

To effectively convey technical designs, specifications, and production requirements, ASME Y14.5 is an indispensable standard. Guidelines for dimensioning and tolerancing methods are provided by Y14.5, which was developed by the American Society of Mechanical Engineers (ASME). This facilitates clear communication among designers, manufacturers, and inspectors. In this piece, I’ll explain what ASME Y14.5 is, why it’s important, and how it affects the engineering industry.

The Purpose and Scope of ASME Y14.5

The standards established by ASME Y14.5 serve as the basis for developing comprehensive engineering drawings and specifications. Its major goal is to standardize the way dimensions, geometric tolerances, and other criteria are written and understood. By eliminating room for interpretation and improving product quality and interchangeability, this standard guarantees that designers’ intentions are communicated clearly throughout production.

Key Concepts in ASME Y14.5

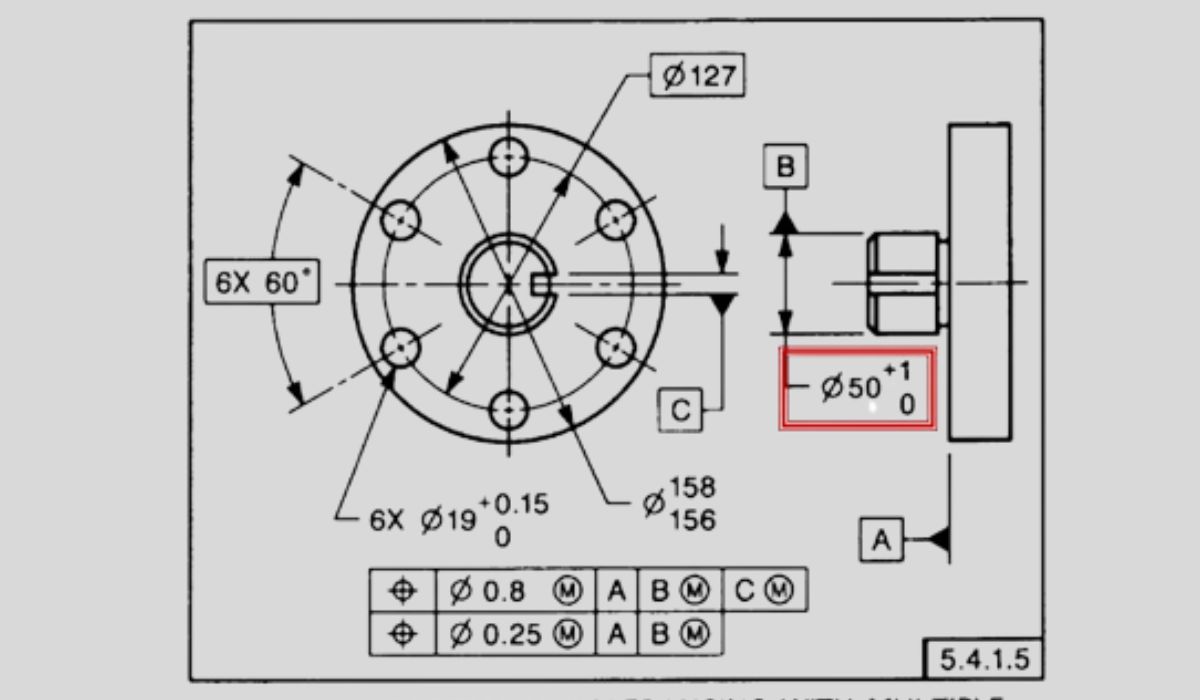

Tolerances, precision, and the appropriate units of measurement are all discussed in Y14.5, which details the proper way to express dimensions on engineering drawings. In order to precisely depict feature sizes and shapes, it specifies several dimensioning approaches as bilateral, unilateral, and geometric dimensioning and tolerancing (GD&T).

Geometric Tolerancing

For engineers to describe allowable variations in shape, orientation, position, and runout of features, GD&T is a crucial part of Y14.5. To guarantee the interchangeability and compatibility of functional parts during assembly, it includes symbols for geometric constraints like as concentricity, perpendicularity, and flatness.

Datum System

Datum reference frames are introduced in Y14.5 to define the coordinates (points, lines, or planes) that are utilized to calculate geometric and dimensional tolerances. From the design phase to quality control, the datum system guarantees constant measurement and interpretation.

Benefits of ASME Y14.5 Implementation

Errors and misunderstandings among stakeholders are reduced when design purpose is clearly and uniformly communicated.

Enhanced Communication

By outlining precise tolerancing standards, Y14.5 helps manufacturers produce products that fit, look, and perform as expected.

Improved Manufacturing Process

Higher product quality, lower variability, and increased performance are all achieved through the Y14.5-specified tolerances and geometric controls, which are in line with client requirements.

Increased Product Quality

Designers, engineers, manufacturers, and inspectors who wish to work within the confines of ASME Y14.5 must first receive the appropriate training. It is common practice for businesses to provide staff with training in dimensioning and tolerancing so that they are familiar with the standard and any updates made to it.

Evolution of ASME Y14.5

Over time, ASME Y14.5 has changed to reflect developments in technology, production methods, and international initiatives to standardize these areas. Engineers and professionals working in dimensional management should read up on the changes to ensure they are in line with current standards.

The American National Standard for Dimensioning and Tolerancing (ASME Y14.5) is a fundamental document in the engineering industry. The goal of this standard is to ensure that all technical drawings and specifications adhere to the same standards when it comes to how measurements, tolerances, and other important requirements are expressed and understood. Engineers, designers, manufacturers, and inspectors may all work together more efficiently and keep product quality high if they all adhere to ASME Y14.5.

The concept of dimensioning is central to ASME Y14.5. Tolerancing, accuracy, and unit requirements for representing dimensions on engineering drawings are all laid forth in the standard. Features’ sizes and shapes are described through the use of dimensioning techniques including bilateral and unilateral dimensioning as well as geometric dimensioning and tolerancing (GD&T). Engineers can use GD&T symbols like concentricity, perpendicularity, and flatness to specify the allowable range of variation in the shape, orientation, placement, and runout of features. By clearly conveying geometric requirements, we can make sure that our products’ individual parts are designed to work together and that our assemblies are built to last.

ASME Y14.5 also introduces the datum system, which is a crucial feature. Dimensional and geometric tolerances have points, lines, and planes that are established by datum reference frames. Using this method, measurements and their interpretation are standardized from the design phase through quality control. The datum system ensures consistent dimensionality and enables thorough inspection of parts through the use of a standard reference.There are many upsides to adopting ASME Y14.5. Errors and misunderstandings can be avoided and teamwork and productivity can improve when design purpose is conveyed clearly and consistently. The standard aids production facilities in attaining precision and uniformity, which cuts down on wasteful rework and guarantees components will fit together as planned and perform as intended. Higher product quality, reduced variability, and enhanced performance are all results of the stringent tolerances and geometric controls specified in Y14.5, which help to satisfy customer expectations and boost satisfaction.

Training and adherence are crucial for successful implementation of ASME Y14.5. Companies frequently provide training courses on dimensioning and tolerancing to make sure their staff members use the methods correctly. To guarantee conformity with current criteria and best practices in the industry, it is essential to keep up with the standard’s most recent modifications and upgrades.

Over time, ASME Y14.5 has progressed to accommodate new technologies, altered production methods, and international standardized approaches. In order to stay in compliance with regulations and take advantage of new best practices, engineers and other professionals working in dimensional management must keep up with these changes.

Conclusion

In conclusion, ASME Y14.5 is a crucial standard in the engineering sector because it establishes a shared vocabulary for clear communication and guarantees reliable, consistent application of design specifications. Implementing it leads to better teamwork, more efficient production, and higher-quality final goods. Organizations may improve their engineering processes, cut down on wasteful rework, and satisfy their customers by following ASME Y14.5.