Melamine board has become one of the most versatile and cost-effective materials in modern construction, furniture-making, and interior design. It is widely known for its smooth, decorative surface and durability, yet many people still have questions about what it truly is, how it is made, and whether it is safe and worth using. In simple terms, melamine board is a particleboard or MDF core coated with a thin layer of melamine resin-infused paper. This outer layer is what gives it its scratch-resistant, moisture-resistant, and aesthetically appealing qualities. The material is popular for making cabinets, wardrobes, office furniture, and wall panels. Understanding melamine board is important because its performance and value vary greatly depending on the quality, type, and intended use. Choosing the right melamine board can save costs, improve durability, and achieve the desired appearance in your project without overspending.

One of the key benefits of melamine board is its ability to mimic expensive wood grains and colors at a fraction of the price. For homeowners and designers, it provides the freedom to create elegant interiors without the cost of solid wood or high-end veneers. For manufacturers, melamine board offers easy machinability, meaning it can be cut, drilled, and shaped without complex equipment. Its uniform surface allows for precise manufacturing, making it ideal for modular furniture systems. However, not all melamine boards are created equal, and understanding their variations can help you avoid common pitfalls. Factors like thickness, core material, surface quality, and edge protection determine the overall strength and longevity of the board. In this guide, we will explore everything from the manufacturing process to practical tips on selecting the best melamine board for your needs. By the end, you will have the knowledge to make informed, confident decisions when working with this material.

What is Melamine Board?

Melamine board is essentially an engineered wood product made by bonding decorative paper infused with melamine resin to a wood-based core, usually particleboard or medium-density fiberboard (MDF). The melamine resin itself is a thermosetting plastic that becomes hard and durable when cured under heat and pressure. This resin provides the board with resistance to scratches, heat, stains, and some degree of moisture. While melamine is the decorative surface, the strength of the board largely depends on the density and quality of the core material. The melamine layer can come in a variety of colors, patterns, and textures, ranging from high-gloss finishes to natural wood grains. The result is a ready-to-use panel that requires no painting or finishing. This makes it a preferred choice in industries where time efficiency and cost savings are important. Despite its benefits, melamine board should not be mistaken for solid wood; it has limitations in terms of structural load and heavy outdoor use.

The Manufacturing Process of Melamine Board

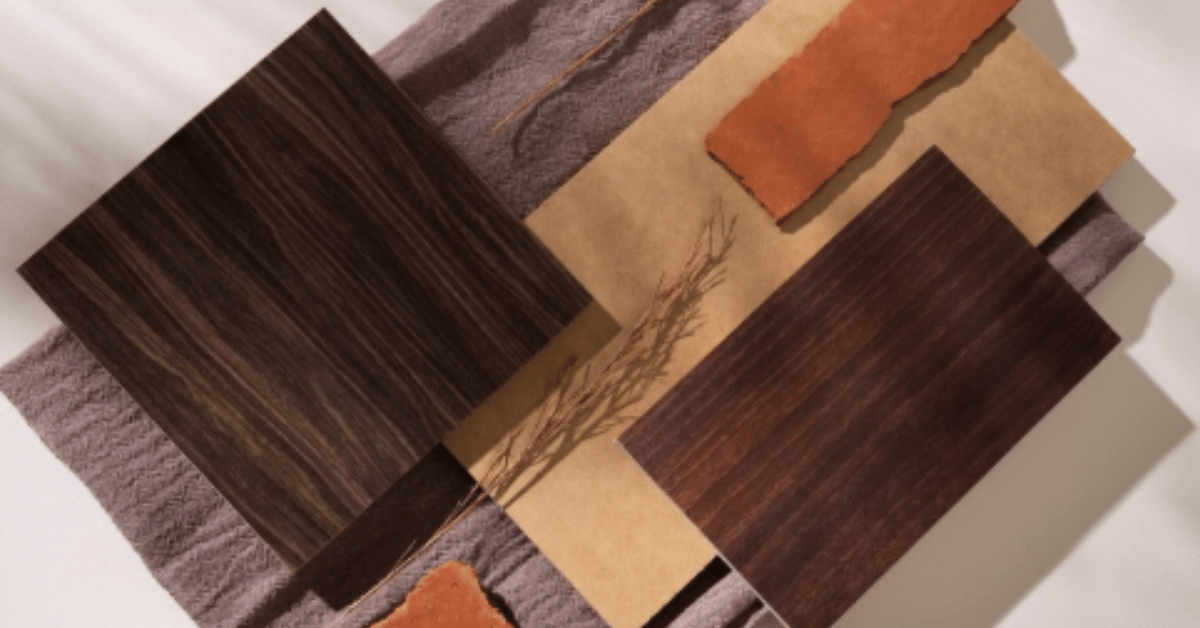

The production of melamine board begins with selecting the core material, which can be particleboard or MDF. The core is made by combining wood particles or fibers with a bonding resin and pressing them into dense, flat sheets. Decorative paper is printed with the desired pattern or color and then soaked in melamine resin. This resin-saturated paper is carefully placed onto the surface of the core board. The assembly is fed into a hot press machine, where heat and pressure cause the melamine resin to cure and bond permanently to the core. Once cooled, the boards are trimmed to precise dimensions and checked for surface quality. Depending on the intended application, manufacturers may apply melamine on one or both sides of the board. Edge banding, a protective strip, can be applied to cover exposed edges and enhance durability. Modern manufacturing techniques allow for a wide range of colors, textures, and even embossed finishes that replicate the feel of real wood or stone.

Types of Melamine Board

Melamine boards are available in multiple types depending on the core material, finish, and intended application. Core types include particleboard-based melamine, which is lightweight and cost-effective, and MDF-based melamine, which offers a smoother surface and better machining qualities. In terms of finishes, you can find plain solid colors, wood grain designs, high-gloss reflective surfaces, and textured finishes for a more natural feel. Double-sided melamine boards have the decorative layer on both sides, making them ideal for furniture where both sides are visible. Single-sided boards are typically used for wall paneling or cabinet interiors. Fire-resistant melamine boards are also available, made with special additives to slow the spread of flames. Moisture-resistant versions contain water-repelling agents and are ideal for kitchen and bathroom use. The choice of melamine board depends largely on where and how it will be used, as each type offers different performance characteristics and price points.

Advantages of Melamine Board

Melamine board is widely appreciated for its blend of affordability, aesthetics, and ease of maintenance. Its surface is pre-finished, meaning there is no need for painting, varnishing, or sealing. This saves both time and labor costs. The melamine layer is resistant to scratches and household chemicals, making it suitable for high-use areas like kitchens and offices. Its variety of colors and textures gives designers the flexibility to achieve different styles without compromising on budget. Compared to natural wood, melamine board is more consistent in quality and dimension, as it does not warp or crack easily under normal indoor conditions. It is also easier to clean—usually requiring only a damp cloth and mild detergent. Environmentally, many melamine boards are made from recycled wood fibers, which helps reduce waste. For projects where appearance, cost, and durability must be balanced, melamine board provides a practical solution without significant compromise.

Disadvantages and Limitations

Despite its many benefits, melamine board has certain limitations that users should consider. The most common drawback is its susceptibility to water damage along exposed edges. While the melamine surface itself is moisture-resistant, water can penetrate unsealed edges and cause the core to swell. This makes it unsuitable for prolonged exposure to high humidity or outdoor use unless specially treated. Additionally, melamine board is not as strong as solid wood when it comes to supporting heavy loads over long spans. Screws can loosen if over-tightened or placed too close to the edges, which may require special hardware for secure fastening. Repairs to damaged melamine surfaces are difficult, as chips or scratches cannot be easily sanded or refinished. The production process also involves formaldehyde-based resins, and while most boards meet emission standards, sensitive users may prefer low-emission or formaldehyde-free options. Understanding these limitations helps in planning projects where melamine board can perform at its best without premature failure.

Common Applications of Melamine Board

Melamine board is used across multiple industries due to its versatility. In the furniture sector, it is a staple for making cabinets, shelves, wardrobes, and office desks. Its pre-finished surface reduces the need for painting, making manufacturing faster and more cost-efficient. In interior design, melamine board serves as wall paneling, closet interiors, and partition systems. In retail spaces, it is often used for display fixtures, as it combines attractive finishes with durability. Educational institutions use melamine boards for desks, storage units, and library furniture due to their ease of cleaning and maintenance. Kitchens and bathrooms benefit from moisture-resistant melamine boards, particularly in cabinetry and shelving. For budget-conscious projects, melamine board offers an appealing alternative to laminated plywood or veneered MDF, delivering style and function without exceeding budget constraints. This wide range of applications demonstrates the adaptability of melamine board in both residential and commercial settings.

Table 1: Key Specifications of Melamine Board

| Feature | Description |

|---|---|

| Core Material | Particleboard or MDF |

| Surface Finish | Melamine resin-coated decorative paper |

| Thickness Range | 6mm to 25mm |

| Standard Sizes | 1220mm x 2440mm, custom sizes available |

| Edge Treatment | Edge banding for moisture protection |

| Resistance Properties | Scratch, heat, and stain resistant |

| Applications | Furniture, cabinetry, wall paneling, shelving |

Durability and Maintenance

The durability of melamine board depends largely on its core quality and how it is installed. High-density MDF cores tend to offer better resistance to impact and wear compared to low-density particleboard. Edge sealing is essential to prevent moisture damage, especially in kitchens and bathrooms. For cleaning, non-abrasive cloths and mild cleaners are recommended to preserve the surface finish. While melamine is scratch-resistant, dragging heavy or sharp objects across its surface can cause marks. Repairs are challenging, so preventive care is key. Over time, well-maintained melamine boards can retain their appearance and functionality for many years, making them a reliable choice for long-term use. Regular inspection of joints, edges, and fastening points can help extend the lifespan of melamine-based furniture and installations, ensuring they remain structurally sound and aesthetically pleasing.

Comparing Melamine Board with Other Materials

When compared to solid wood, melamine board is lighter, more affordable, and more consistent in quality. Unlike wood, it does not require regular sealing or polishing. Against plywood, melamine offers a smoother, ready-to-use surface without additional laminating costs. However, plywood often surpasses melamine in structural strength and water resistance. Compared to high-pressure laminates (HPL) applied over MDF or particleboard, melamine is thinner and generally less expensive but offers fewer customization options. For applications requiring frequent heavy use or exposure to moisture, HPL or plywood may be preferable. For indoor furniture and decorative panels, melamine provides an excellent balance of cost and performance. Choosing between these materials often depends on the specific needs of the project, budget constraints, and expected lifespan of the finished product.

Table 2: Melamine Board vs. Other Materials

| Material | Cost | Durability | Moisture Resistance | Maintenance |

|---|---|---|---|---|

| Melamine Board | Low to Moderate | Moderate to High | Moderate | Low |

| Plywood | Moderate to High | High | High | Moderate |

| Solid Wood | High | Very High | Variable | High |

| HPL over MDF | Moderate | High | Moderate to High | Low |

Safety and Environmental Considerations

Melamine board is generally safe for indoor use, provided it meets formaldehyde emission standards set by regulatory bodies. Many manufacturers produce low-emission or CARB-compliant boards to ensure indoor air quality remains within safe limits. When cutting or machining melamine board, fine dust particles can be released, so wearing protective masks is recommended. From an environmental perspective, melamine boards often contains recycled wood fibers, reducing the demand for virgin timber. However, it is not biodegradable and can be difficult to recycle due to the resin coating. Some companies are exploring eco-friendly resins and recycling methods to reduce environmental impact. For consumers, choosing certified low-emission products and following proper installation practices can help maintain safety and environmental responsibility.

Buying Tips for Melamine Board

When purchasing melamine board, start by determining the specific application and environment in which it will be used. For high-moisture areas like kitchens, opt for moisture-resistant grades with proper edge sealing. Check the density of the core material, as higher density usually means better durability and screw-holding capacity. Inspect the surface for defects such as bubbles, scratches, or uneven finishes. If visible edges are part of the design, ensure the board comes with high-quality edge banding. For large projects, consider ordering from the same production batch to maintain color consistency. Price should be balanced with quality, as the cheapest boards may not perform well in demanding conditions. Always request material data sheets from suppliers to confirm specifications and compliance with safety standards.

Conclusion

Melamine board stands out as a highly practical, affordable, and aesthetically versatile material that meets the needs of modern interiors and furniture design. It offers the elegance of high-end finishes without the cost and maintenance demands of solid wood or laminates. While it does have certain limitations—particularly regarding edge moisture vulnerability and heavy structural loads—these can be managed with proper selection, installation, and maintenance. The wide variety of colors, textures, and core options means there is a melamine board suitable for almost any indoor application. For those balancing budget, style, and functionality, melamine board remains a smart choice. As technology advances, improvements in moisture resistance, eco-friendly resins, and recycling processes will only enhance its value and sustainability. As one furniture designer aptly put it, “Melamine is the unsung hero of affordable design—stylish, reliable, and ready to perform.” By understanding its strengths and limitations, you can ensure that melamine board works to your advantage in both residential and commercial projects.

FAQs

1. What is melamine board made of?

Melamine board consists of a particleboard or MDF core covered with a decorative paper layer impregnated with melamine resin. This resin-coated surface makes it durable, scratch-resistant, and easy to clean.

2. Is melamine board waterproof?

The melamine surface is moisture-resistant, but the core can swell if water penetrates exposed edges. Proper edge sealing is necessary for use in humid areas.

3. Can melamine board be used outdoors?

Melamine board’s designed for indoor applications. Prolonged exposure to sunlight, rain, or humidity can cause damage, swelling, and discoloration.

4. How do you cut melamine board without chipping?

Use a fine-toothed carbide-tipped blade or a specialized melamine saw blade. Applying masking tape along the cut line can also help reduce chipping.

5. Is melamine board safe for indoor use?

Yes, if it meets low formaldehyde emission standards such as CARB Phase 2 or E1 ratings. Always choose certified boards from reputable suppliers.