The conical rod is a critical yet often underappreciated component in modern engineering, manufacturing, and structural applications. In the first 100 words, it is essential to understand that a conical rod is not just a cylindrical rod with a taper; it is a precisely designed element that facilitates load distribution, vibration control, and aesthetic structural integration across various industries. From aerospace to construction, the conical rod’s unique geometry allows for stress optimization and material efficiency. Engineers and designers rely on its tapering structure to reduce weight while maintaining high strength and rigidity, fulfilling functional and economical requirements simultaneously.

The conical rod’s relevance has expanded in modern design due to the increasing emphasis on material optimization, energy efficiency, and precise mechanical performance. Unlike cylindrical rods, conical rods provide graduated thickness, which allows for variable load management along the rod’s length. This tapered design can significantly reduce bending moments and improve resistance to torsional stresses. Furthermore, the conical rod’s geometric profile enables engineers to tailor components to specific use cases, such as in automotive suspension systems, industrial machinery, and architectural frameworks. “In engineering, shape is as critical as material,” notes Dr. Helen Sutherland, a structural design expert, emphasizing the conical rod’s role in modern mechanical applications. Its versatility also extends to aesthetic considerations in visible structures, where conical rods contribute to visual balance while delivering structural functionality.

Understanding the Geometry of a Conical Rod

A conical rod is essentially a rod with a continuously tapering diameter from one end to the other. This tapering can be linear or curvilinear, depending on the application and mechanical requirements. Linear tapers are the most common due to manufacturing simplicity, while curvilinear or exponential tapers are preferred in high-performance scenarios requiring stress optimization. The rod’s geometry is typically defined by three primary parameters: base diameter, tip diameter, and overall length. These dimensions directly influence the rod’s load-bearing capacity, vibration response, and bending stiffness.

The taper angle of a conical rod is another essential factor. Even small variations in the taper can significantly affect mechanical performance. A shallow taper provides gradual load transition and higher flexibility, while a steep taper increases rigidity and concentrates stress at the smaller end. Material selection interacts with geometry to determine the rod’s suitability for specific environments. For example, high-strength steel with a slight taper is preferred in automotive driveshafts, whereas lightweight aluminum or composite materials are favored in aerospace applications. This geometric flexibility allows conical rods to serve in both functional and decorative roles, bridging the gap between engineering efficiency and design sophistication.

| Parameter | Description | Typical Range | Application Example |

|---|---|---|---|

| Base Diameter | The wider end of the rod | 20–200 mm | Industrial machinery supports |

| Tip Diameter | The narrower end of the rod | 5–100 mm | Aerospace struts, structural connectors |

| Length | Total rod length from base to tip | 100–3000 mm | Architectural rods, mechanical linkages |

| Taper Angle | Angle of diameter reduction | 1–10 degrees | Load distribution optimization |

The selection of taper type and ratio requires careful consideration of mechanical stress distribution. Engineers use finite element analysis (FEA) to simulate stress patterns along the rod and predict potential failure points. This predictive modeling ensures that the conical rod’s geometry is optimized for both material efficiency and performance reliability. Such analysis also accounts for external factors such as temperature fluctuations, dynamic loads, and potential vibration resonances, which are particularly important in high-speed machinery and aerospace systems. The conical rod’s versatility is evident in how minor adjustments in its geometric parameters can result in substantial improvements in performance without increasing material consumption or production costs.

Materials Commonly Used for Conical Rods

The material of a conical rod significantly influences its performance characteristics, durability, and application suitability. Metals are the most commonly used materials due to their strength, machinability, and predictable mechanical properties. Steel alloys, aluminum, titanium, and copper alloys are widely used in various industries. Each metal offers a unique balance of strength, weight, and corrosion resistance, which must be carefully matched to the application requirements.

Composite materials, including carbon fiber and fiberglass, have become increasingly popular for high-performance conical rods. Their lightweight nature combined with superior tensile strength makes them ideal for aerospace, automotive, and sports equipment applications. “Modern composite rods can outperform traditional metals in strength-to-weight ratios,” explains Dr. Alan Reyes, a materials scientist specializing in advanced composites. Plastics and polymers, though less common, are sometimes used in low-load applications where corrosion resistance and electrical insulation are necessary. Selecting the appropriate material involves evaluating mechanical load, environmental exposure, thermal considerations, and cost-effectiveness. In addition, surface treatments such as anodization, plating, or coating may further enhance durability and resistance to wear, particularly in industrial or marine environments.

| Material | Properties | Typical Applications | Advantages |

|---|---|---|---|

| Steel Alloys | High strength, moderate weight | Industrial machinery, construction | Cost-effective, high load capacity |

| Aluminum | Lightweight, corrosion-resistant | Aerospace, automotive | Easy to machine, reduces structural weight |

| Titanium | High strength, corrosion-resistant | Aerospace, medical | Exceptional durability, lightweight |

| Carbon Fiber Composites | Extremely high strength-to-weight | Sports, aerospace | Lightweight, customizable |

| Plastics/Polymers | Low strength, corrosion-resistant | Electrical insulation, light-duty applications | Cost-effective, corrosion-proof |

Material choice is also influenced by fabrication techniques. For instance, steel rods can be forged, machined, or cold-rolled to achieve precise tapering, while carbon fiber rods require molding and layering methods. Material anisotropy in composites must be considered to ensure load-bearing performance aligns with expected stress directions. This meticulous attention to material behavior ensures that conical rods maintain mechanical integrity under operational conditions, a factor critical in high-stakes industries such as aerospace and automotive engineering.

Manufacturing Processes for Conical Rods

The production of conical rods involves a variety of manufacturing processes depending on material, size, and tolerance requirements. Conventional methods for metallic rods include turning, forging, extrusion, and milling. Turning on a lathe remains the most widely used process for precision tapering, especially for small to medium-sized rods. Forging offers high strength and fatigue resistance due to grain alignment, while extrusion allows continuous production of rods with consistent profiles.

For composite rods, manufacturing techniques differ significantly. Filament winding, pultrusion, and molding are commonly used to achieve tapered geometries while maintaining high strength and uniform material distribution. Advanced CNC (Computer Numerical Control) machining has also revolutionized the production of conical rods, allowing complex tapers, precise diameters, and tight tolerances that were previously difficult to achieve. Automation in manufacturing has increased consistency, reduced waste, and enabled mass production of rods for industrial applications. Quality control is paramount; each rod must undergo dimensional verification, mechanical testing, and surface inspection to ensure adherence to stringent engineering standards.

| Manufacturing Method | Suitable Materials | Key Advantages | Typical Tolerance |

|---|---|---|---|

| CNC Turning | Steel, Aluminum, Titanium | High precision, customizable | ±0.05 mm |

| Forging | Steel, Titanium | Enhanced strength, fatigue resistance | ±0.1 mm |

| Extrusion | Aluminum, Plastics | Continuous production, cost-effective | ±0.2 mm |

| Filament Winding | Carbon Fiber, Fiberglass | High strength-to-weight, lightweight | ±0.1 mm |

| Pultrusion | Composites | Uniform cross-section, efficient | ±0.15 mm |

The integration of additive manufacturing (3D printing) has further expanded possibilities for conical rod fabrication. This method allows rapid prototyping, complex internal structures, and material combinations that traditional manufacturing cannot easily achieve. In applications where weight reduction and structural optimization are crucial, 3D-printed rods can feature internal lattices or graded densities, significantly improving performance. Engineers now have unprecedented control over the final product, ensuring that every conical rod meets exact specifications for its intended function.

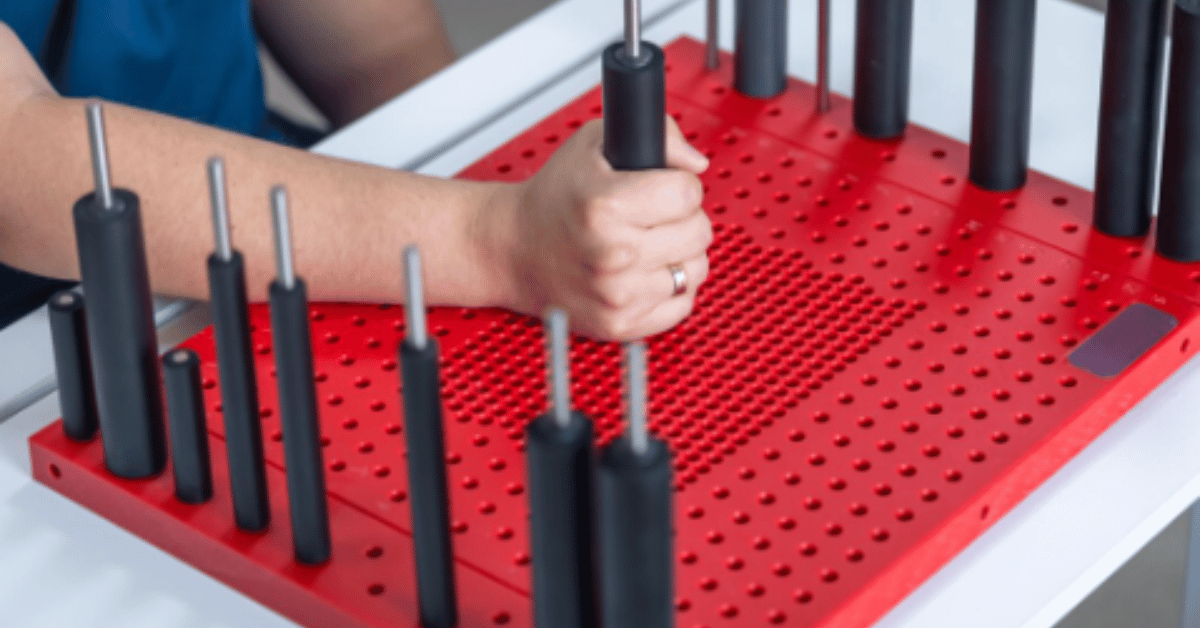

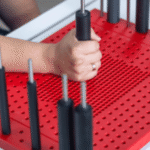

Applications of Conical Rods Across Industries

Conical rods are widely used in diverse industries because of their ability to handle variable loads, reduce material usage, and provide tailored structural performance. In the aerospace sector, they serve as lightweight yet strong components in wing spars, landing gear supports, and fuselage frameworks. Their tapering design reduces weight at non-critical areas while maintaining strength where needed. Automotive applications include drive shafts, suspension linkages, and steering columns, where the conical geometry optimizes torque transmission, vibration damping, and fatigue resistance. In industrial machinery, conical rods are integrated into presses, conveyor systems, and robotic arms, balancing strength, precision, and wear resistance. Architectural and civil engineering applications also leverage the aesthetic and functional advantages of conical rods in columns, railings, and tensioned structures. The rod’s adaptability ensures engineers can tailor mechanical, structural, and visual characteristics for each unique scenario, highlighting the critical interplay between design and function.

In addition, conical rods are increasingly used in marine and offshore engineering, where weight, corrosion resistance, and load distribution are essential. Tapered rods in ship masts, rigging supports, and underwater frameworks resist bending and torsional stress while minimizing material fatigue under dynamic environmental loads. Medical devices also benefit from conical rods, particularly in orthopedic implants, surgical instruments, and prosthetic supports. Their geometry allows precise force distribution along the device, improving patient outcomes while reducing material waste. Even consumer products, such as high-performance sports equipment, leverage conical rod designs for shafts, poles, and frames where weight-to-strength ratios are critical. Across all sectors, the conical rod’s combination of geometric flexibility, material efficiency, and mechanical reliability underscores its versatility. “The conical rod bridges the gap between structural necessity and creative design,” remarks engineer Mark Linton, emphasizing its multi-disciplinary impact.

Mechanical Performance and Load Distribution

The mechanical performance of a conical rod depends heavily on its taper, material selection, and the type of load applied. Axial loads, bending moments, and torsional stresses interact with the rod’s geometry to determine overall behavior. In axial applications, the gradual taper allows uniform stress distribution, reducing peak stress at the base and enhancing fatigue resistance. Under bending, the conical rod’s changing cross-section alters the moment of inertia along its length, which can either increase flexibility or enhance rigidity depending on design intent. Torsional performance is similarly influenced by the rod’s smallest diameter; careful analysis ensures that twisting does not exceed material limits, preventing structural failure.

Finite element analysis (FEA) and analytical modeling are commonly used to evaluate mechanical performance. Engineers simulate the interaction between load, geometry, and material to optimize design, often iterating multiple prototypes before final production. Dynamic analysis is critical in rotating machinery and aerospace components, where vibration frequency and resonance can compromise structural integrity. By adjusting the taper angle, engineers can shift resonance frequencies and reduce the risk of mechanical failure. Proper surface finishing and heat treatment can further enhance fatigue resistance and extend the lifespan of the rod, particularly in applications with repetitive or fluctuating loads. The combination of careful geometry, material selection, and stress analysis ensures that conical rods perform reliably under demanding operational conditions.

| Load Type | Performance Consideration | Recommended Design Approach | Industry Example |

|---|---|---|---|

| Axial Load | Uniform stress distribution | Moderate taper with high-strength material | Aerospace wing spars |

| Bending Load | Moment of inertia variation | Taper optimized for flexibility or rigidity | Architectural beams |

| Torsion | Twist resistance | Smaller diameter reinforcement or material enhancement | Drive shafts |

| Dynamic Loads | Vibration and resonance control | Adjust taper and surface treatment | Industrial rotating machinery |

| Fatigue Loads | Long-term stress cycles | Material selection and heat treatment | Automotive suspension rods |

Design Guidelines and Standards

Designing a conical rod requires adherence to specific engineering standards and guidelines to ensure safety, efficiency, and manufacturability. Organizations such as ASTM (American Society for Testing and Materials) and ISO provide frameworks for tolerances, material testing, and mechanical performance verification. Design considerations include the rod’s taper ratio, length-to-diameter ratio, surface finish, and permissible stress levels. Engineers must also account for environmental factors, including temperature, humidity, corrosion potential, and exposure to chemicals or UV radiation, which can degrade performance over time.

The use of computer-aided design (CAD) tools and finite element simulations has become standard practice for conical rod design. These tools allow precise visualization of stress distribution, deformation under load, and potential failure points before physical production. Design safety factors are incorporated based on industry norms, operational conditions, and material fatigue properties. Modular approaches are sometimes adopted for adjustable or interchangeable rod components, particularly in large-scale machinery or architectural frameworks. By combining standard guidelines, digital modeling, and practical experience, engineers can ensure that conical rods meet stringent performance and safety requirements while optimizing cost and efficiency.

| Design Parameter | Consideration | Recommended Practice | Industry Standard Reference |

|---|---|---|---|

| Taper Ratio | Load distribution and rigidity | Use analytical and FEA modeling | ASTM E8/E8M |

| Length-to-Diameter Ratio | Buckling and bending resistance | Optimize for structural application | ISO 6892 |

| Surface Finish | Wear and fatigue resistance | Polishing or coating as required | ISO 4287 |

| Material Stress Limits | Safety factor inclusion | 1.5–3 times expected load | ASTM A370 |

| Environmental Impact | Corrosion or UV degradation | Material selection and coating | ISO 9223 |

Maintenance and Lifespan Considerations

A conical rod’s operational lifespan is determined by a combination of design, material choice, environmental exposure, and maintenance practices. Routine inspection for wear, corrosion, and micro-cracking is essential, particularly in dynamic applications such as automotive drive shafts or rotating industrial machinery. Lubrication, surface coatings, and protective treatments can significantly extend life by reducing friction and preventing environmental degradation. Regularly scheduled stress tests and non-destructive evaluation (NDE) techniques, such as ultrasonic testing or dye penetrant inspection, are employed in critical applications to detect early-stage defects before catastrophic failure occurs.

Maintenance strategies vary by industry. In aerospace, inspection cycles are highly regimented, with each rod tracked for operational hours, load history, and environmental exposure. Industrial applications may rely on predictive maintenance, where sensors monitor vibration, strain, and temperature to forecast wear and schedule proactive replacements. Architectural and consumer applications require less frequent maintenance but still benefit from routine inspection for corrosion or mechanical loosening. Proper storage, handling, and installation techniques also affect longevity, preventing bending or accidental stress concentration. Through a combination of preventative maintenance and careful monitoring, the operational lifespan of conical rods can be maximized, ensuring both safety and cost efficiency.

| Maintenance Aspect | Recommended Approach | Frequency | Impact on Lifespan |

|---|---|---|---|

| Inspection | Visual and NDE testing | Monthly/annually depending on application | Prevents catastrophic failure |

| Lubrication | Apply appropriate lubricant | Regular operation cycles | Reduces friction, wear |

| Surface Treatment | Coating or anodization | At production or refurbishment | Enhances corrosion resistance |

| Load Monitoring | Sensors for strain and vibration | Continuous | Enables predictive maintenance |

| Storage & Handling | Avoid bending, exposure to moisture | Ongoing | Prevents early material degradation |

Case Studies: Conical Rod Applications

Aerospace Industry

A leading aerospace manufacturer integrated conical rods into the wing spar design of a regional jet, reducing overall weight by 15% while maintaining structural integrity. The tapered geometry allowed stress redistribution along the spar, enhancing fatigue life and reducing maintenance frequency. Finite element simulations verified load handling under turbulent conditions, demonstrating the rod’s critical role in operational safety.

Automotive Industry

In high-performance sports cars, conical drive shafts replaced traditional cylindrical shafts, resulting in improved torque transfer and reduced vibration. Lightweight aluminum rods with slight tapers enhanced acceleration and handling while decreasing drivetrain wear. Engineers used dynamic modeling to optimize taper angles and material thickness, showcasing the rod’s performance benefits in real-world automotive applications.

Architectural Applications

A contemporary suspension bridge utilized conical rods for tensioned support cables. The taper allowed material efficiency, reducing overall mass without compromising load-bearing capacity. The visual aesthetics were equally enhanced, as the tapered rods contributed to a sleek, modern design. Maintenance inspections showed minimal wear over a decade, validating the rod’s long-term durability.

Conclusion

The conical rod represents a unique intersection of geometry, material science, and engineering ingenuity. Its tapering design offers exceptional versatility, allowing tailored load distribution, reduced material usage, and optimized mechanical performance across industries. From aerospace to automotive, industrial machinery to architecture, conical rods enhance both structural integrity and aesthetic appeal. The integration of advanced materials, manufacturing processes, and digital modeling ensures that these rods meet demanding operational requirements while maintaining cost-effectiveness and sustainability. Proper maintenance, environmental considerations, and adherence to design standards further extend their lifespan, ensuring reliable performance under challenging conditions. As technology continues to evolve, conical rods are poised to become smarter, lighter, and more efficient, solidifying their role as indispensable components in modern engineering. As Dr. Helen Sutherland emphasizes, “Conical rods embody the principle that precise geometry and thoughtful material choice can transform ordinary structural elements into extraordinary engineering solutions.” Their continued innovation will shape the future of mechanical design, architectural elegance, and industrial efficiency for decades to come.

FAQs

Q1: What is the main advantage of a conical rod over a cylindrical rod?

A1: The primary advantage lies in load distribution and material efficiency. The taper allows stress to be spread along the rod’s length, reducing weight while maintaining strength.

Q2: Which materials are most commonly used for conical rods?

A2: Common materials include steel, aluminum, titanium, and composite materials such as carbon fiber. Material choice depends on load requirements, weight, and environmental conditions.

Q3: Can conical rods be used in high-vibration applications?

A3: Yes. Properly designed conical rods can handle vibration efficiently by optimizing taper angle, material, and surface treatments, reducing resonance and fatigue risks.

Q4: How are conical rods manufactured?

A4: Manufacturing methods include CNC turning, forging, extrusion, filament winding for composites, and increasingly, additive manufacturing for complex geometries.

Q5: How long does a conical rod last?

A5: Lifespan depends on material, design, operational load, and maintenance. Regular inspection and protective treatments can significantly extend operational life.