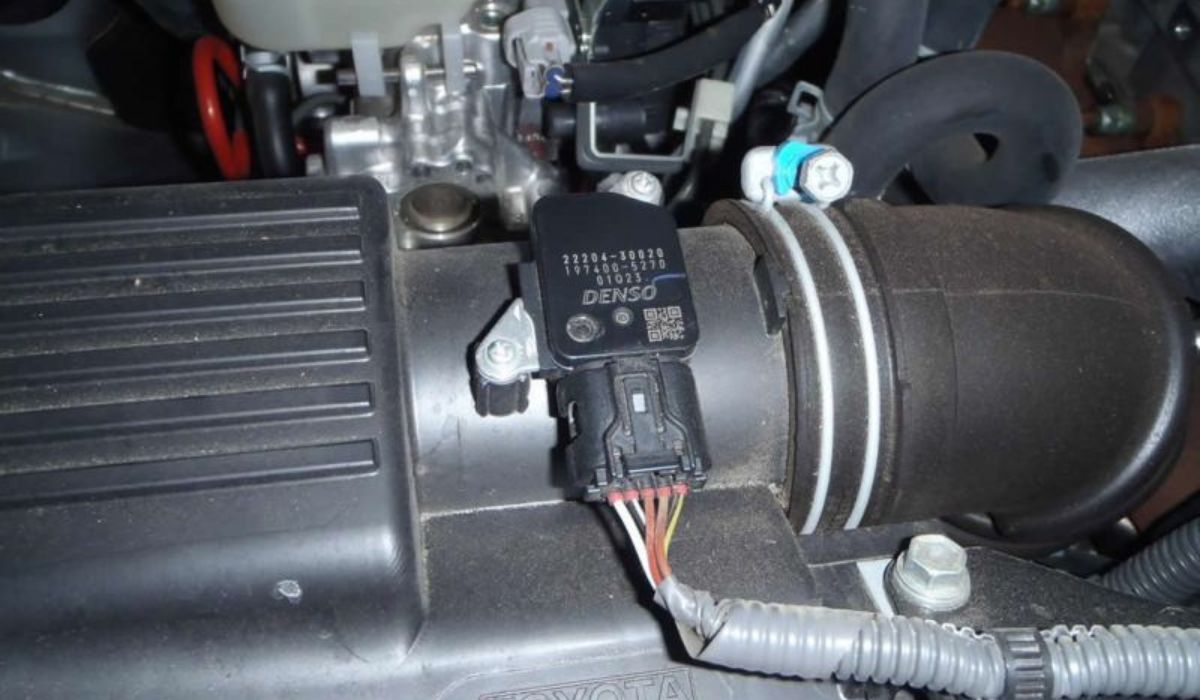

Precision and efficiency are paramount in the complex field of modern automobile engineering. When it comes to the workings of an automobile, the Mass Air Flow (MAF) sensor is an integral part of the system. This modest device’s purpose is crucial in guaranteeing peak engine performance, enhanced fuel economy, and less emissions, yet it might pass unnoticed at first. The Mass Air Flow sensor is discussed in detail, along with its function, significance, and effect on the modern automobile industry.

The Essence of the Mass Air Flow Sensor

A vehicle’s electronic control system would be incomplete without the Mass Air Flow sensor. Its major purpose is to supply the engine control unit (ECU) with real-time data on the volume of air entering the engine through the intake manifold. After collecting this information, the optimal ratio of fuel to air for combustion can be calculated. In order for an engine to function properly, this fine equilibrium is required.

Types of Mass Air Flow Sensors

The hot wire sensor and the vane meter sensor are the two most prevalent MAF sensors installed in current automobiles.

Hot Wire Sensor: One variety of MAF sensor is the “hot wire” variety, which uses a thin wire heated to an appropriate temperature. The wire is cooled by the incoming air as it flows past it. The mass of the entering air is determined by the ECU by measuring the amount of electrical current needed to keep the wire at a constant temperature.

Vane Meter Sensor: Sensor for Vane Meter The vane meter A movable flap (vane) is integrated into the airflow to function as the MAF sensor. The vane rotates because of the force exerted by the incoming air on it as it enters the engine. The Electronic Control Unit (ECU) takes the vane’s rotational motion and translates it into an electrical signal to calculate the air density.

The Significance of Accurate Measurements

The engine’s efficiency relies on precise readings from the Mass Air Flow sensor. Its information is used to control things like fuel injection, ignition timing, and emissions. An inaccurate air-to-fuel ratio, decreased power, and increased emissions can all arise from a faulty mass airflow (MAF) sensor.

Challenges and Maintenance

Despite their importance, Mass Air Flow sensors are not without its problems. Dirt, dust, and grease can accumulate on the sensor’s sensitive parts and interfere with its ability to function, resulting in erroneous results. In addition, the sensor’s functionality can be impaired by sudden and dramatic shifts in temperature. To keep the sensor functioning accurately and reliably over time, routine maintenance and cleaning are required.

Technological Advancements

The sensors used in automobiles are always being upgraded to keep up with technological advances. The longevity and precision of contemporary Mass Air Flow sensors are the result of the use of cutting-edge materials and designs. Some modern automobiles also have extra sensors, such as an Intake Air Temperature (IAT) sensor, that send more precise information to the engine control unit (ECU).

Conclusion

Although the Mass Air Flow sensor is a rather unassuming component, its effects are significant. In order to maximize engine performance, fuel efficiency, and emissions management, it is crucial to guarantee the correct ratio of air to fuel. The Mass Air Flow sensor is an example of the sophisticated infrastructure that allows today’s vehicles to perform at their peak, and it is a prime example of how far automotive engineering has come. A well-oiled driving machine is the result of regular maintenance, cutting-edge technology, and a thorough understanding of this part.

Frequently Ask Questions (FAQs)

What is a Mass Air Flow sensor?

The Mass Air Flow (MAF) sensor is an integral part of today’s vehicles since it determines how much air is being sucked into the engine. It feeds information in real time to the engine control unit (ECU), which then uses it to calibrate the air-fuel ratio.

How does a MAF sensor work?

Hot wire MAF sensors and vane meter MAF sensors are the two most common varieties. Vane meter sensors use a moveable vane that reacts to the airflow, whereas hot wire sensors employ a heated wire to measure the heating effect of outgoing air. The ECU uses the electrical signals generated by the sensor to determine the mass of the air being drawn in.

Why is the Mass Air Flow sensor important?

Reliability of the MAF sensor is critical for controlling emissions, conserving fuel, and keeping the engine running smoothly. The engine control unit (ECU) can optimize the engine’s performance through the use of fuel injection, ignition timing, and other factors when given accurate measurements.

What problems can arise from a faulty MAF sensor?

Inadequate fuel economy, decreased power, and elevated emissions are all possible results of a defective mass air flow sensor. Rough idle, sluggish acceleration, and even stalling are all possible engine problems.

How can I tell if my MAF sensor is failing?

A check engine light, poor fuel economy, rough idling, slow acceleration, and a perceptible loss of engine power are typical symptoms of a faulty MAF sensor. Error codes can be examined by diagnostic equipment to establish if the MAF sensor is malfunctioning.