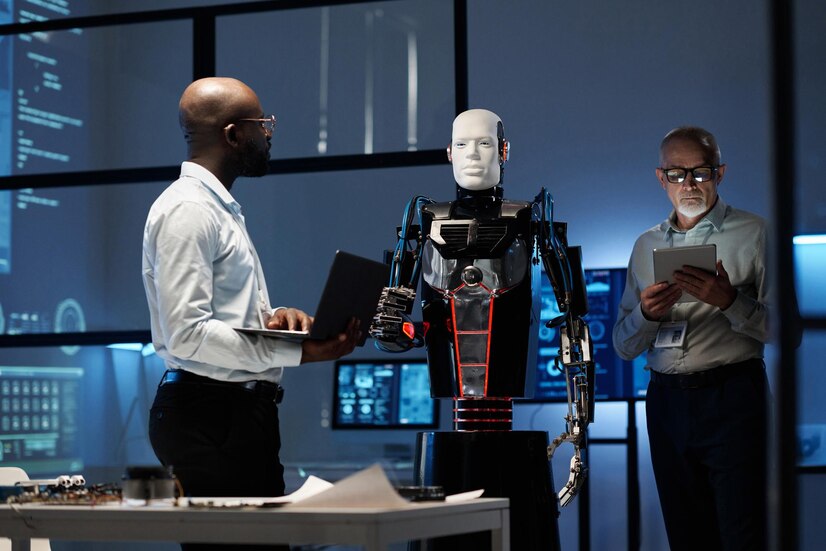

The notion of a universal, multi-talented, humanoid robot remains a pop culture fascination. With recent developments at major robotic companies receiving plenty of media attention, it’s easy to envision that such human-esque machines are just on the horizon for the public. However, substantial hardware, software, and technological hurdles remain, pushing this wide-spread adoption of these types of robots at least a decade into the future.

So, what is the next, attainable step for robotic automation? The team at Quasi Robotics believes it will be an ecosystem of interoperating AI-powered robots – each with the perfect degree of versatility for its designated role, and each working harmoniously to deliver end-to-end automation for any workflow.

Technical Challenges of General-Purpose Robots

While the concept of a single, adaptable robot holds appeal, limitations in current robot technology make this vision difficult to achieve. This is largely due to the needs surrounding:

Hardware Optimization:

- Varying tasks have different physical demands and may require different hardware.

Industrial robots built for strength and speed will lack the precision required for intricate assembly or medical procedures, and vice versa.

- Blending these vastly different capabilities into a single machine presents trade-offs in strength, precision, engineering, and cost.

Software Complexity:

- Intelligence algorithms are also tailored to their intended tasks and vary greatly. Focusing on accuracy requires different robot programming than focusing on surveillance or speed or agility.

- Crafting a singular software suite to encompass such diverse capabilities significantly adds to development time and complexity.

Proficiency Relies on Focused Learning:

- Robots master complex tasks through iterative practice and extensive training data. Specialized robots refine their skills faster within a defined operational domain, ultimately outperforming general-purpose robots.

- At least for now, attempts at universality still run into the question of: ‘do we want one robot to do many things badly,’ or ‘do we want several, specialized robots to do specific things well.”

Quasi Robotics: Harnessing the Power of Integrated Automation

By focusing on targeted applications, robotic developers like Quasi enable businesses to see tangible benefits quickly. However, it is crucial that these specialized robots fluidly integrate – not only with other robots from the same company, but also with any solution, machine, or system for true facility automation.

Quasi Robotics doesn’t just develop robots for specific tasks; their mission is to design and integrate an entire end-to-end automation system.

This is the power of the Q.AI Integrated Automation Platform. It seamlessly orchestrates a collaborative network of purpose-built robots and sophisticated technological components to revolutionize diverse industries, comprised of three core pillars:

1) Purpose-Built Mobile Robots:

- Model R2: An autonomous mobile robot, fit with a robotic arm for material handling and object manipulation. R2’s unmatched agility, including autonomous motion and grip calculations, combine with advanced intelligence for quick adaptation and versatility in task completion. Easily integrate with existing machines for sorting, assembly, patient care, and a myriad of other material handling tasks.

- Model C2: An autonomous mobile cart designed intra-facility transport of materials, tools, and supplies. C2 navigates autonomously and with precision within small workspaces and around tight turns while integrating seamlessly with existing workflows. Perfect for tasks like machine tending and mid-workflow deliveries that require no process interruption.

2) Q.AI Intelligence: The Decision-Making Engine

- Specialized Algorithms: The brain of the Q.AI Integrated Automation Platform is a proprietary set of sophisticated algorithms. Refined through years of testing and optimization, Q.AI is tailored for perfected robot navigation, task execution, sensor data analysis, and resource allocation.

- Continuous Learning and Optimization: Q.AI Intelligence constantly learns and adapts through experience. By processing data from robots, sensors, and user input, the system acquires new skills and shares them among all fleet robots instantly.

3) Cloud Connect: Intuitive Control and Data Visualization

- Command Center: Cloud Connect acts as a central hub for system control, allowing users to assign tasks, modify schedules, and manage robot fleets with an intuitive, graphical interface accessible from any tablet.

- Data Analytics Powerhouse: Transform raw data into actionable business intelligence with customizable dashboards that offer complete views of system performance, identifying areas for improvement and enabling predictive maintenance.

- Traceability and Audit Logs: Comprehensive records are maintained of all robot actions and system activity. This detailed audit log provides businesses with complete traceability, ensuring clear accountability and simplifying regulatory compliance efforts.

Benefits of an Integrated Approach

The integrated approach of the Q.ai Integrated Automation Platform unlocks a multitude of benefits for businesses:

- End-to-End Productivity: Integrated automation takes a holistic approach to process optimization – uniting the abilities of robots, sensors, and software platforms. This interconnected ecosystem allows real-time data exchange, intelligent task allocation, and automated decision-making, leading to significant efficiency gains and increased productivity.

- Never-ending Flexibility and Scalability: Modular robot designs, adaptable software, and standardized communication protocols enable businesses to easily scale. New robots and functionalities can be easily integrated into the existing ecosystem, future-proofing automation investments and allowing businesses to adapt to changing market demands.

- Data-Driven Insight: Sensor data gathered throughout the workflow provides insights into process efficiency, identifying bottlenecks and potential areas for improvement By analyzing real-time and historical data, businesses can make data-driven decisions to optimize workflows, reduce waste, and achieve continuous process improvement.

Integration Enables Specialized and Adaptable Automation

True automation solutions must be responsive to changing business requirements. The Q.AI Integrated Automation Platform delivers the flexibility needed for long-term success.

Conclusion

The future of robotics isn’t about futuristic humanoids, but about integrated systems delivering real-world results today. Purpose-built robots, like those in the Q.AI Integrated Automation Platform, excel at specific tasks and work harmoniously within a larger workflow. This approach delivers immediate efficiency gains, empowers workers, and unlocks the potential for continuous data-driven improvement.

To learn more about Quasi Robotics solutions, visit: www.quasi.ai