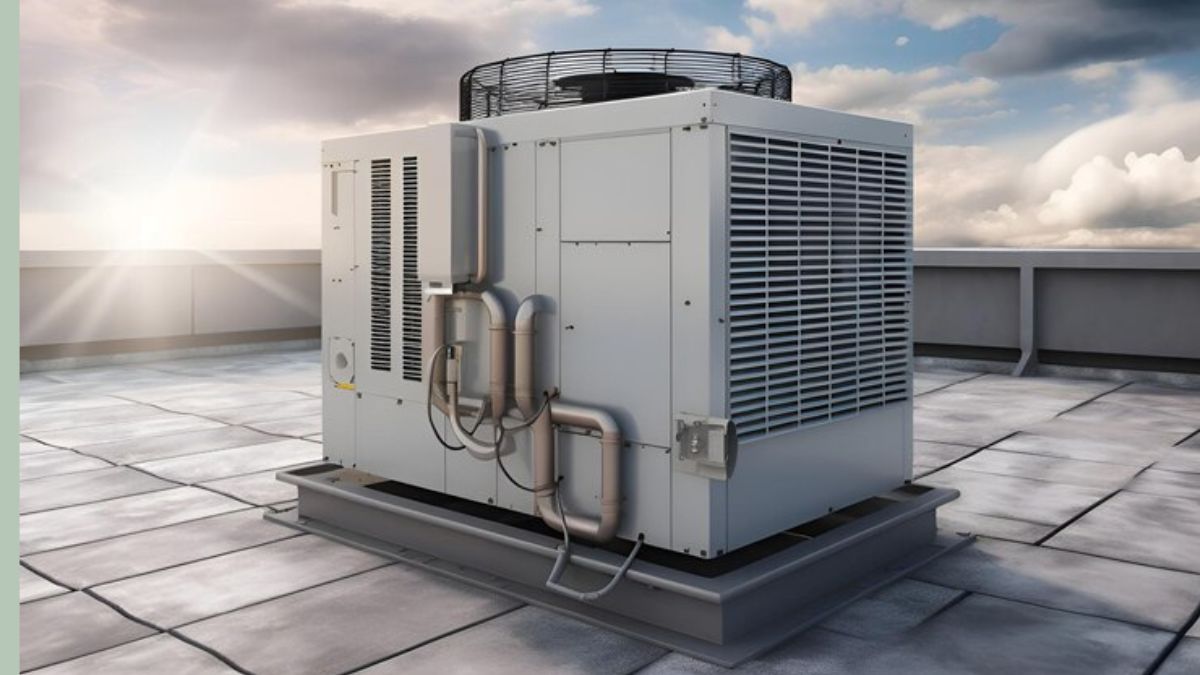

In the intricate world of industrial operations, there exists a silent hero that often goes unnoticed but plays a pivotal role in various processes: compressed air. This invisible force is essential for a wide range of applications, from powering tools and machinery to packaging and automation. However, its significance becomes most apparent when businesses strive to optimize their operations and reduce operating costs. In this article, we will explore the importance of compressed air efficiency and unveil strategies and solutions that can help businesses harness its potential.

Understanding the Importance of Compressed Air Efficiency

Compressed air, in its essence, is a form of stored energy that powers a multitude of industrial applications. It is versatile, clean, and relatively easy to distribute throughout a facility. Yet, its convenience can lead to its misuse, resulting in energy wastage and increased operating costs.

Efficient utilization of compressed air is not just a matter of cost savings; it’s also an environmentally responsible practice. Wasteful use of compressed air translates to higher energy consumption, increased greenhouse gas emissions, and a larger carbon footprint for businesses.

One crucial step in improving compressed air efficiency is to conduct a compressed air audit. This assessment involves evaluating the entire compressed air system, from the air compressor to distribution and end-use applications. By identifying areas of inefficiency and waste, businesses can take targeted actions to enhance their compressed air systems.

Choosing the Right Compressed Air Solutions Company

To embark on the journey toward compressed air efficiency, it is essential to collaborate with a reputable compressed air solutions company. These companies specialize in providing expertise, equipment, and services to help businesses optimize their compressed air systems.

When selecting a compressed air solutions company, consider factors such as their experience, track record, and the range of services they offer. A well-established company will typically have a team of experts who can conduct compressed air audits, provide recommendations, and assist with the implementation of energy-saving solutions.

Upgrading with Air Compressor Dryers

One key component that plays a critical role in compressed air quality and efficiency is the air compressor dryer. These devices remove moisture and contaminants from the compressed air, ensuring that it meets the required quality standards.

There are various types of air compressor dryers available, each designed for specific applications. Refrigerated dryers, for example, are commonly used for general-purpose compressed air systems, while desiccant dryers are ideal for applications requiring extremely dry air. Selecting the right dryer type for your specific needs is essential for maintaining both the quality and efficiency of your compressed air.

Ensuring Efficiency with Proper Air Compressor Parts

The efficiency and reliability of a compressed air system are heavily dependent on the quality of its components, including air compressor parts. Regular maintenance and the use of high-quality, compatible parts are essential to ensure that the system operates at its best.

Air compressor parts that are often replaced or upgraded include filters, valves, gaskets, and belts. Ensuring that these components are in good condition and correctly matched to the system’s specifications can significantly contribute to improved efficiency and reduced energy consumption.

Maximizing Performance with Air Compressor Service

Regular maintenance and servicing of air compressors are paramount to maintaining peak performance and efficiency. Professional air compressor service providers offer expertise in diagnosing issues, conducting routine maintenance, and repairing or replacing components as needed.

Scheduled maintenance can help prevent unexpected breakdowns, reduce downtime, and extend the lifespan of air compressors. Additionally, service providers can optimize the compressor’s settings for energy efficiency and address any potential leaks or inefficiencies in the system.

Implementing Energy-Saving Strategies

Enhancing compressed air efficiency also involves implementing energy-saving strategies tailored to the specific needs of a business. Variable speed drives (VSDs) and demand-based control systems are effective tools for optimizing energy usage by adjusting compressor output to match the actual demand.

Another crucial aspect is leak detection and repair. Even minor leaks in a compressed air system can result in significant energy wastage over time. Identifying and fixing these leaks is a cost-effective measure that can lead to substantial energy savings.

Conducting Compressed Air Audits

To gain a comprehensive understanding of the efficiency of your compressed air system, consider conducting a compressed air audit. This detailed assessment involves a thorough evaluation of the entire system, from the air compressor itself to the distribution network and end-use applications.

During an audit, experts measure factors such as air pressure, flow rates, and energy consumption. They also identify areas where improvements can be made, such as reducing pressure drops, optimizing piping layouts, and eliminating wasteful uses of compressed air. The insights gained from a compressed air audit serve as a roadmap for enhancing efficiency and reducing operational costs.

Case Studies and Success Stories

Real-world examples often provide the most compelling evidence of the benefits of compressed air efficiency. In numerous industries, businesses have successfully implemented strategies and solutions to enhance their compressed air systems, resulting in tangible improvements.

For instance, a manufacturing facility in the automotive industry reduced its energy consumption by 30% after implementing a combination of air compressor upgrades, leak detection, and demand-based control. Similarly, a food processing plant optimized its compressed air system, resulting in reduced downtime, improved product quality, and significant cost savings.

These success stories underscore the practicality and effectiveness of investing in compressed air efficiency measures.

Sustainability and Environmental Considerations

In an era where sustainability and environmental responsibility are paramount, efficient compressed air systems align with these values. By minimizing energy consumption, businesses reduce their carbon footprint and contribute to a more sustainable future.

Efficient compressed air systems also result in fewer greenhouse gas emissions, making them an eco-friendly choice for environmentally conscious businesses. Furthermore, energy-efficient practices often go hand in hand with reduced operating costs, making them a win-win proposition.

Conclusion

Compressed air efficiency is not merely a technical consideration; it’s a strategic advantage that can significantly impact a business’s bottom line and its environmental footprint. Collaborating with a reputable compressed air solutions company, upgrading with air compressor dryers, utilizing high-quality air compressor parts, and prioritizing air compressor service are all steps in the right direction.

By implementing energy-saving strategies, conducting compressed air audits, and learning from case studies and success stories, businesses can unlock the full potential of their compressed air systems. In doing so, they enhance their operational efficiency, reduce costs, and contribute to a more sustainable future. Compressed air may be invisible, but its benefits to businesses are undeniable, and its efficient use is both an opportunity and a responsibility.