Gelamento, derived from the Italian word for freezing, is a term commonly associated with the process of gelation in various scientific and industrial contexts. Gelation refers to the transition of a system from a liquid to a semi-solid state, forming a gel-like structure. This process plays a critical role in food science, cosmetics, pharmaceuticals, material science, and environmental applications. In this article, we delve into the science behind gelamento, explore its diverse applications, and examine its implications in modern industries.

Understanding Gelamento: The Science Behind Gelation

Gelation is a complex phenomenon involving physical or chemical interactions that transform a liquid into a gel. A gel is a three-dimensional network structure that traps liquid within its matrix, giving it a unique combination of solid and liquid properties. The formation of a gel can be induced by various mechanisms:

- Physical Gelation: This occurs through non-covalent interactions, such as hydrogen bonding, van der Waals forces, or electrostatic interactions. Examples include gelatin and agar, which form gels upon cooling.

- Chemical Gelation: This involves the formation of covalent bonds between polymer chains, creating a stable network. Silicone gels and epoxy resins are common examples.

- Thermally Induced Gelation: Certain polymers undergo gelation when exposed to specific temperature conditions. For instance, methylcellulose gels form upon heating.

- Ionotropic Gelation: In this process, gelation is induced by ionic cross-linking. Sodium alginate forms gels when exposed to divalent cations like calcium.

- Enzymatic Gelation: Enzymes can catalyze gelation by modifying the molecular structure of a substance, as seen in the production of cheese through the action of rennet.

Understanding the mechanisms of gelamento is crucial for optimizing its use in various applications, ensuring desired properties like texture, stability, and functionality.

Applications of Gelamento

1. Food Industry

Gelation is a cornerstone of food science, influencing the texture, stability, and sensory attributes of numerous products. Examples include:

- Dairy Products: Yogurt, cheese, and pudding rely on gelation to achieve their creamy texture.

- Confectionery: Gummies, marshmallows, and jelly desserts use gelling agents like gelatin and pectin.

- Bakery Products: Gelation improves the moisture retention and shelf life of bread and pastries.

- Meat Processing: Gelation helps bind water and fat, enhancing the texture and appearance of sausages and meatballs.

2. Pharmaceuticals and Medicine

Gelation plays a pivotal role in drug delivery, wound healing, and tissue engineering:

- Drug Delivery Systems: Hydrogels can encapsulate drugs for controlled release, improving efficacy and patient compliance.

- Wound Dressings: Gels provide a moist environment that promotes healing and reduces pain.

- Tissue Engineering: Scaffolds made from gels mimic the extracellular matrix, supporting cell growth and tissue regeneration.

- Vaccines: Some vaccine formulations use gels to stabilize active ingredients and enhance their effectiveness.

3. Cosmetics and Personal Care

The cosmetic industry extensively employs gelation to develop products with desirable textures and performance characteristics:

- Skin Care: Moisturizers, serums, and masks use gels for smooth application and hydrating effects.

- Hair Care: Styling gels and conditioners benefit from gelation for improved hold and consistency.

- Makeup: Foundations and primers use gel-based formulations for a lightweight feel and even coverage.

4. Material Science and Engineering

Gelation is integral to the development of innovative materials:

- Smart Gels: These are responsive to stimuli like pH, temperature, or light, with applications in sensors and actuators.

- Aerogels: Ultra-lightweight materials with exceptional insulation and adsorption properties.

- Adhesives and Sealants: Gel-based adhesives offer strong bonding and flexibility.

- 3D Printing: Gels are used as bioinks and structural supports in additive manufacturing.

5. Environmental Applications

Gelation contributes to sustainable practices and environmental conservation:

- Water Purification: Hydrogels can remove pollutants and heavy metals from water.

- Oil Spill Cleanup: Gel-based absorbents help contain and recover oil spills.

- Agriculture: Hydrogels improve soil water retention and nutrient delivery.

Factors Influencing Gelamento

The gelation process is influenced by various factors that determine the properties of the final gel:

- Concentration of Gelling Agents: Higher concentrations lead to stronger gels, while lower concentrations produce softer gels.

- Temperature: Many gels require specific temperature conditions for formation, such as cooling for gelatin or heating for methylcellulose.

- pH: The acidity or alkalinity of a solution can impact the gelation process, especially in pectin-based gels.

- Ionic Strength: The presence of ions affects the stability and rigidity of gels, as seen in alginate gels cross-linked with calcium ions.

- Time: The duration of gelation affects the uniformity and strength of the gel network.

- Additives: Ingredients like sugar, salt, or alcohol can modify gelation properties, enhancing or inhibiting the process.

Advances in Gelamento Research

Recent advancements in gelation research have opened new avenues for innovation:

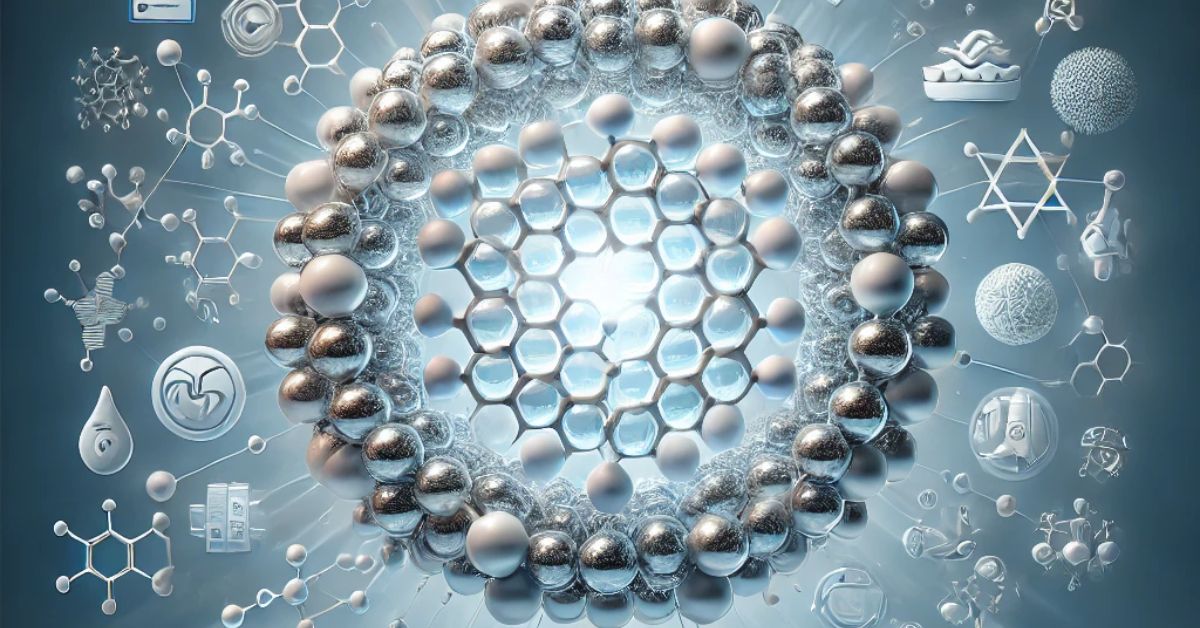

1. Nanogels and Microgels

These tiny gel particles are gaining attention for their versatility in drug delivery, diagnostics, and bioimaging. Their small size allows for targeted delivery and minimal invasiveness.

2. Hybrid Gels

Combining natural and synthetic polymers results in gels with enhanced properties, such as increased biocompatibility and mechanical strength. Hybrid gels find applications in regenerative medicine and bioelectronics.

3. Stimuli-Responsive Gels

These gels change their properties in response to external stimuli, enabling applications in sensors, actuators, and smart drug delivery systems.

4. Sustainable Gels

Research focuses on developing gels from renewable resources to reduce environmental impact. Examples include gels derived from seaweed, cellulose, or plant proteins.

Benefits of Gelamento

The process of gelation offers several advantages across industries:

- Versatility: Gels can be tailored for diverse applications, from food to pharmaceuticals to engineering.

- Improved Functionality: Gelation enhances the texture, stability, and performance of products.

- Sustainability: Many gels are biodegradable and derived from renewable resources, contributing to eco-friendly practices.

- Controlled Release: Gels enable precise delivery of active ingredients, improving efficacy and minimizing waste.

- Innovation: Advances in gelation technology drive the development of cutting-edge materials and solutions.

Challenges and Future Directions

Despite its benefits, gelation poses certain challenges:

- Consistency: Achieving uniform gelation can be difficult due to variations in temperature, pH, or ingredient quality.

- Cost: High-quality gelling agents and sophisticated processing methods can be expensive.

- Shelf Life: Some gels may degrade over time, losing their desired properties.

- Scalability: Transitioning from laboratory-scale gelation to industrial-scale production requires careful optimization.

Future research aims to address these challenges by developing robust, cost-effective, and scalable gelation processes. Emerging fields like bioprinting, nanotechnology, and green chemistry are expected to further expand the potential of gelamento.

Conclusion

Gelamento, or the process of gelation, is a transformative phenomenon with wide-ranging applications in food, medicine, cosmetics, and beyond. Its ability to create versatile, functional, and sustainable materials has made it a cornerstone of innovation in modern industries. As research continues to advance, gelamento holds the promise of addressing global challenges, from healthcare to environmental sustainability.

FAQs on Gelamento

1. What is gelamento? Gelamento refers to the process of gelation, where a liquid transforms into a semi-solid or gel-like state through physical or chemical interactions.

2. What are the main types of gelation? The main types include physical gelation, chemical gelation, thermally induced gelation, ionotropic gelation, and enzymatic gelation.

3. How is gelation used in the food industry? Gelation is used to improve the texture, stability, and sensory qualities of products like yogurt, cheese, gummies, and bakery items.

4. What are hydrogels, and how are they used? Hydrogels are water-absorbing gels used in drug delivery, wound dressings, tissue engineering, and environmental applications like water purification.

5. What are stimuli-responsive gels? Stimuli-responsive gels change their properties in response to external factors like temperature, pH, or light, making them useful in sensors, actuators, and smart drug delivery systems.

6. What are the challenges of gelation? Challenges include achieving consistent gelation, high costs, limited shelf life, and scalability for industrial production.