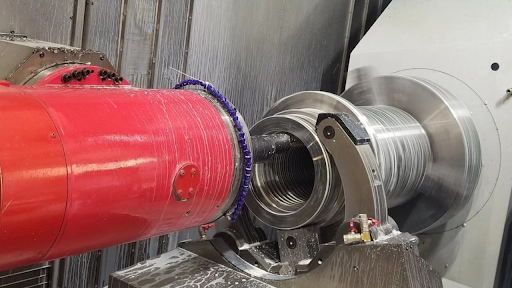

Starting a CNC machining project is a journey where quality, efficiency, and dependability all come together. Obtaining a comprehensive CNC machining quote is an important first step as you traverse the complexities of translating your design concepts into practical, high-quality components. This quotation provides a road map for your manufacturing venture, defining the scope, costs, and dates.

In the dynamic world of precision engineering, a CNC machining quote is more than just a number; it’s a vow to provide meticulously machined components that meet or exceed your exact specifications. A well-crafted CNC machining estimate goes beyond the surface, digging into your project’s technical complexities.

It demonstrates the machining service provider’s knowledge by detailing their understanding of your design requirements, material specifications, and desired tolerances. This initial phase of cnc machining quote establishes the tone for collaboration, transparency, and a shared commitment to seeing your vision through to completion.

A Step-by-Step Guide On Requesting A Quote for CNC Machining Services

Requesting an estimate for CNC machining services is an important step toward making your designs a reality. Understanding the process of obtaining a quote guarantees a seamless and transparent engagement with a CNC machining service provider, whether you are a seasoned engineer or a business owner in need of precise components. This article provides a step-by-step guide to requesting an estimate for CNC machining services.

- Define Your Project’s Needs

Begin by describing your project’s requirements precisely. This includes stating the type of material, the number of parts, the desired tolerances, and any other pertinent information. The more complete your project description, the more accurate and thorough the quote.

- Prepare Technical Drawings Or CAD Models

Provide technical drawings or Computer-Aided Design (CAD) models to accurately represent your design. These files serve as the blueprint for the CNC machining process, allowing the service provider to analyze the project’s complexity and feasibility.

- Material Requirements

Specify the material(s) you require for your project. CNC machining services work with a wide range of materials, including metals, plastics, and composites. Material type, grade, and any particular considerations, such as heat treatment or surface finish needs, should be specified.

- Detail Tolerance and Quality Standards

Specify the tolerances required for your project. CNC machining provides high precision, although the tolerances required vary depending on the part’s function and industry. Communicate any quality standards or certifications that your project must meet.

- Indicate Surface Finish Requirements

If surface finish is important for your project, indicate the finish (for example, polished, anodized, or coated). Surface finishes can influence the selection of machining equipment and techniques, hence influencing the overall cost and timetable.

- Provide Quantity Estimates

Clearly state how many parts you require. CNC machining services frequently provide varied pricing structures based on output volume. Knowing your quantity needs allows the service provider to provide appropriate pricing and delivery timelines.

- Communicate Any Secondary Operations

If your project necessitates additional procedures such as assembly, engraving, or special packaging, make sure to communicate these needs in advance. This guarantees that the CNC machining service provider will quote on all areas of your project.

- Inquire About Lead Times And Delivery

Include your preferred delivery date and inquire about the expected lead time. Understanding the production timetable is critical for project planning and business cooperation.

- To Contact With CNC Machining Service Providers

Contact reliable CNC machining service providers. This can be accomplished by contacting them via their websites, emails, or phone numbers. Prepare extensive information for them and be prepared to explain any special requests or limits.

- Review and Compare Quotes

After receiving estimates from various CNC machining service providers, thoroughly review and compare them. Examine not only the overall price but also the included services, lead times, and any other terms or restrictions.

- Seek Clarifications if Needed

If any portion of the quote is unclear or you have more questions, don’t be afraid to ask the CNC machining service providers for clarification. A clear and open line of communication is critical to the success of any collaboration.

- Make An Informed Decision

After careful consideration, select the CNC machining service provider that best meets your project’s needs, price, and timeframe. Consider their reputation, experience, and customer feedback as further deciding criteria.

Landscape Of CNC Machining Quotes

Obtaining accurate CNC machining quotes is a critical step in realizing a project in the world of precision manufacturing. To establish the cost of translating raw materials into precision-engineered components, a comprehensive study of various elements is required.

- Material Costs

The selection of materials is critical in CNC machining quotations. Different materials have different costs, and the decision is influenced by factors such as the purpose of the part, needed qualities, and budget constraints. The raw materials required for the project are included in the material costs.

- Estimating Machining Time

Estimating the time necessary for machining is critical to the quote. Programming the CNC machine, setting up tools, and carrying out the machining process are all part of this. The machining time is affected by the complexity of the design and the complexity of the features.

- Costs of Tooling And Setup

Each CNC machining project necessitates the purchase of specific tools and setups. Cutting tools, inserts, and other consumables are all included in tooling expenses. Setup expenses include the time and materials required to prepare the CNC machine for the job at hand.

- Labor Costs and Design Complexity

CNC machining requires skilled labor for duties ranging from programming to machine operation. Wages for machinists, programmers, and other project people are included in labor costs. The complexity of the design has a direct impact on the CNC machining quote. Advanced machining techniques, more tool changes, and extended programming time may be required for more complicated designs.

- Surface Finish Specifications And Material Waste

When a project requires certain surface finishes, such as polishing or anodizing, additional processes are required, which affect both time and cost. Surface finish requirements influence the choice of machining tools and processes. Material utilization efficiency is critical. Material waste, or the amount of material discarded during machining, has an impact on the final cost.

- Secondary Operations And Administrative Costs

The CNC machining quote includes any secondary procedures, such as assembly and further finishing processes. Providers assess the time and resources needed for additional jobs.

The quote includes overhead expenditures for facility upkeep, utilities, and administrative charges. These expenses help fund general operations and support services.

Conclusion

Requesting a quote for CNC machining services needs careful planning, effective communication, and a careful examination of the quotes received. By following this step-by-step guidance, you can ensure that the CNC machining service provider understands your project completely, resulting in accurate quotations and successful project outputs. In essence, calculating CNC machining quotes is a complex procedure that necessitates a careful balancing of many aspects.

READ: The Environmental Benefits of Buying Used Industrial Equipment