To find injection molding customer’s journey may be successful only with strategic planning and intelligent tactics. In this guide, five tested and determined services are explained from different aspects including digital marketing power and strategic partnerships that reach the right clientele.

This guide insight allows you to be well positioned in the market upon your expansion offshore, with utmost confidence in traction and revenue generation.

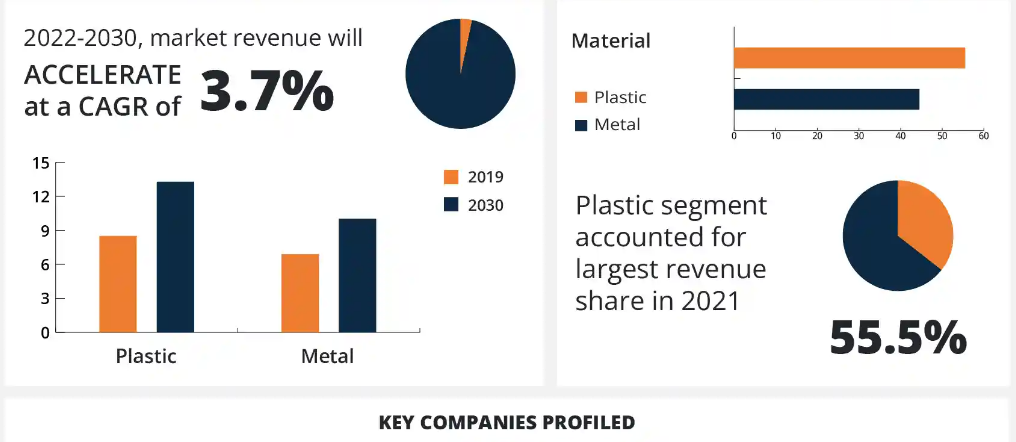

Understanding the Injection Molding Market!

- Benefits of specializing in specific sectors

- Precision Engineering

Focusing on precision sectors, firms boost their appeal to clients needing exacting standards. Specialized tools and software, like CAD and CAM, are vital. Companies optimize processes for parts like gears and bearings. Market dominance becomes achievable by excelling in precision.

- Custom Fabrication

In custom fabrication, versatility attracts a diverse clientele. Skilled labor and advanced machinery, including 3D printers, are investments. Success hinges on adapting to client specifications with agility and innovation.

- High Tolerance

High tolerance sectors require meticulous attention to detail. Industries such as aerospace and electronics depend on components meeting strict criteria. Utilizing high-precision equipment and quality assurance control systems ensures compliance. Mastery in high tolerance practices garners trust from sectors where error margins are nearly zero.

- Rapid Prototyping

Rapid prototyping accelerates product development and market entry. Employing technologies like SLA and SLS, companies can swiftly produce prototypes. This agility enables feedback incorporation and design iteration. Attracting clients across sectors, rapid prototyping services promise reduced development times and cost savings.

- Analyzing market demand and customer needs

- Demand Forecasting

Accurate demand prediction requires the study of what transpired before and what is currently happening such as past sales data and market trends. The applications of AI in ML boost the outcome precision.

A correct forecast of future demand eliminates an excess of stocks, which helps firms to avoid wastage that might be highly expensive in the future. Trend anticipation signifies that companies become ahead of the curve by adjusting their production methods in time and thus offering the best offers on the market.

- Customer Segmentation

Splitting the clients up in segmenting is a way for businesses to be able to suit their customers. Collecting information about purchased goods and preferences paves the way to segmentation. Auto, medical, and other sectors all find benefit in close cooperation with custom plastic injection molding services providers.

The results of successful segmentation – when implemented right – customers’ satisfaction is high, and they remain loyal, thus contributing to the overall sales growth.

- Market Analysis

A study, in-depth, of the market helps to reveal clearly such aspects as competition and expectations of the customers. Proper market gap analysis makes the firms easily innovate. Data-driven decisions create the fuel to drive things forward. Gathering the latest regulatory changes and technology’s keeping up will help the sector’s long-term results in the injection molding industry.

Networking and Relationship Building!

- Industry Conferences

Industry conferences provide a platform for showcasing innovations and technologies. Attendees, ranging from engineers to executives, seek the latest trends. Networking opportunities abound, fostering partnerships. Face-to-face interactions at these events often lead to lasting business relationships.

- Online Forums

Online forums act as digital congregations for industry professionals. Members exchange knowledge, solve problems, and discuss trends. Active participation establishes expertise and credibility. These platforms facilitate connections beyond geographical limitations, enhancing visibility in the injection molding community.

- Trade Associations

Trade associations bring together companies with shared interests. Membership offers access to industry research, standards, and best practices. Regular meetings and newsletters keep members informed. Collaborating on common challenges strengthens the industry as a whole, creating growth opportunities.

- Networking Events

Networking events are crucibles for forging new business connections. Informal settings encourage open dialogue among participants. Sharing experiences and challenges can reveal potential collaborators. Events specifically tailored for the injection molding sector enhance the relevance of connections made, driving mutual business success.

Digital Marketing and Online Presence!

- SEO Strategies

Implementing SEO strategies enhances visibility online. Keywords related to injection molding should populate website content. Optimizing site speed and mobile responsiveness attracts more visitors. Regularly updating blogs with industry insights improves ranking. Effective SEO drives targeted traffic, increasing potential customer engagement.

- Social Media

Social media platforms serve as powerful tools for engagement. Sharing updates, achievements, and industry news keeps followers informed. Interactive posts encourage dialogue with the audience. Leveraging hashtags related to injection molding expands reach. Consistent presence on social media builds brand recognition and loyalty.

- Content Marketing

Content marketing establishes authority in the injection molding sector. Publishing case studies, whitepapers, and how-to guides educate the audience. Video content showcasing machinery and processes attracts attention. Tailoring content to answer common customer queries positions a company as a knowledgeable leader.

Offering Superior Quality and Customization!

- Quality Assurance

The existence of quality control measures in injection molding is equally essential. A worth-repeating sample cycle and an exhaustive test program help to guarantee the consistency of product quality. Complicated measuring machineries for CMMs are the last one in the digitization chain which confirms part dimensions. ISO certificates signify the dedication to Vigorance. Producing products of high quality not only develops customer trust but also creates a reliable end-user.

- Custom Solutions

In a complex environment where one size does not fit all, custom solutions provide a chance to adequately meet various customers’ needs. Cooperating closely with clients is an important factor for a project to be completed and meet deadlines.

The advantage of mold injection is that even complex geometries and precision can be achieved. Customization grows in-product capability while also improving customer satisfaction.

- Design Flexibility

Of the several crucial components of innovation, is a paramount one. Identified as a quick prototyping technique, the approach saves time by making the complete cycle of idea, development, assembly, testing, and modification, and the whole process is shortened.

This flexibility, however, makes cusp (or fashion) design valuable as it optimizes form and function. Design flexibility is the key element that speeds up, product development and plays an important role in gaining a competitive advantage in the market.

- Material Selection

What material is will also have an influence on the product’s working. Easily, certain polymers have intrinsic traits that can be different by nature, such as rigidity and stiffness. Engineers provide guidance in selecting the right materials to use in some endeavors.

High-tech materials, like composites, provide benefits that can be used to enrich the products’ features. Highly selected materials that ensure the quality and life span of products are the criterion of environment friendliness.

Strategic Partnerships and Collaborations!

- Joint Ventures

Partnerships give that accumulate resources approving market penetration. Partners both accept risk and stock up knowledge to create novel approaches.

This kind of strategy speeds up entering into the markets which the pioneer is not in yet. In addition, working relations between injection molding agencies and the material suppliers are not maxed out; these show examples of working with influential forces to achieve technology advancements.

- Business Alliances

Business alliances involve partnerships that are jointly formulated by businesses based on their strategic advantages. The strategic collaboration helps to create broader extensions to the networks. Likewise, the sharing of resources can frequently lead to resource efficiency. The involvement of designers and injection molders in the same alliance would prevent bottlenecks in the product development process, hence all their profits.

- Co-Development

Co-development fosters innovation through shared knowledge. Teams from different companies work together on product design and manufacturing challenges. This collaborative approach speeds up problem-solving. Co-developed products often set new industry standards, showcasing the power of collaborative creativity.

- Cross-Promotion

Cross-promotion extends reach to partner audiences, maximizing visibility. Companies exchange marketing spaces, introducing products to new customers. This strategy leverages existing relationships, enhancing brand recognition. Cross-promotion between injection molding companies and their clients showcases the versatility of applications, attracting diverse industries.

Conclusion

Finding injection molding customers may be the art of a business to be able to grow. Utilizing digital transformation, developing alliances, and serving customers with new and improved solutions, are the perfect weapons to amass a big customer base.

Kindly explore this topic in more detail to start establishing your groundwork for becoming more competitive in the upcoming contests.