The term “laminar flow” is used to characterize the unmixed and orderly motion of a fluid in parallel strata, with little or no turbulence or mixing. The purpose of this article is to provide a thorough introduction to laminar flow, including a discussion of its definition, characteristics, affecting factors, and potential applications.

What is Lamina’r Flow

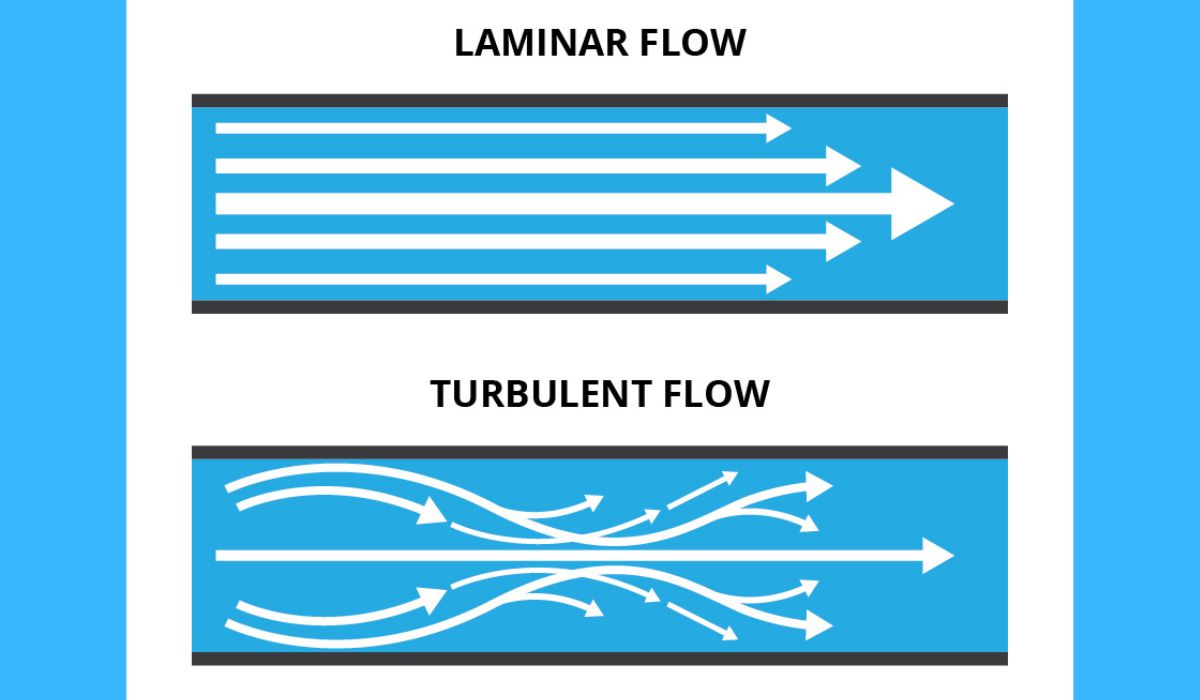

When a fluid is said to be flowing laminarly, it is because its particles are moving in parallel strata without any chaotic mixing or eddies. Lamina’r flow, in contrast to turbulent flow, is defined by the smooth, predictable movement of fluid particles.

Characteristics of Lamina’r Flow

There are several distinguishing features of lamina’r flow that set it apart from turbulent flow:

Streamlined: The fluid flows in layers, with each layer retaining its own speed and direction.

Orderly: The flow pattern is consistent and predictable, with few exceptions.

Low mixing: There is little to no mixing or diffusion between neighboring layers, so few particles or impurities are swept up into the system.

Low energy loss: Laminar flow is more effective than turbulent flow in some circumstances due to the lower energy loss associated with laminar flow.

Low noise generation: Laminar flow, in contrast to turbulent flow, generates less noise because of its smooth and uniform motion.

Factors Influencing Laminar Flow

The incidence and stability of laminar flow can be affected by a number of factors, including:

Velocity of the Fluid

The flow regime is heavily influenced by the fluid’s velocity. When the fluid’s particles have less kinetic energy and move in a more orderly fashion, we call this laminar flow.

Viscosity of the Fluid

The resistance to flow is proportional to the viscosity of the fluid. The increased internal friction associated with a higher viscosity fluid makes laminar flow more likely to occur.

Diameter of the Channel

The occurrence of lamina’r flow is also affected by the size and geometry of the channel through which the fluid is flowing. Laminar flow is more common in narrower channels or pipelines, while turbulent flow is more common in wider ones, especially at higher velocities.

Reynolds Number

The Reynolds number is a dimensionless metric that measures the strength of viscous forces in a fluid compared to inertial forces. At small Reynolds numbers, where viscous forces are most prominent, we observe laminar flow.

Applications of Lamina’r Flow

Since laminar flow is so special, it is used in many different contexts. Here are a few examples of popular uses:

Laminar Flow in Engineering

Engineers rely heavily on laminar flow when developing aerodynamic profiles like airplane wings and sleek automobiles. It aids in reducing air resistance, increasing mileage per gallon, and maximizing system efficiency.

Lamina’r Flow in Medicine

Laminar flow is used in cleanrooms and operating theaters to keep the environment sterile. As a result, patients are safer, infections are avoided, and surgical areas are protected.

Lamina’r Flow in Manufacturing Processes

The semiconductor industry and the pharmaceutical industry are only two examples of manufacturing sectors that use laminar flow. It ensures a regulated setting, blocking the entry of impurities and preserving product integrity.

Lamina’r Flow in HVAC Systems

Laminar flow is commonly used by HVAC systems to deliver filtered and conditioned air throughout a building. It improves indoor air quality and helps reduce the spread of airborne pollutants.

Laminar Flow in Microfluidics

Laminar flow is essential for the exact manipulation and control of microfluidic devices’ tiny fluid volumes. Lab-on-a-chip devices, biological analysis, and chemical analysis can all benefit from this technology.

Lamina’r Flow in Chemical Processing

Laminar flow is crucial in the chemical processing industry for regulating reactions and facilitating effective heat transfer. It assures consistent mixing, lessens the production of waste, and boosts productivity.

Lamina’r Flow in Environmental Sciences

The study of rivers, estuaries, and other natural water bodies, as well as lamina’r flow, has far-reaching significance in environmental studies. Pollutant dispersal, sediment movement, and ecosystem dynamics are all easier to predict when scientists have a firm grasp of laminar flow.

How to Achieve Lamina’r Flow

To achieve lamina’r flow, many elements must be taken into account. To encourage lamina’r flow, you can do things like:

- Choosing the right channel dimensions and shapes.

- Controlling the velocities of fluids within the lamina’r flow regime

- Keeping things as smooth as possible to reduce friction and potential for disturbance.

Challenges in Maintaining Lamina’r Flow

Although lamina’r flow has many practical benefits, it is not always easy to maintain. Some such difficulties include:

- Disturbances from the outside, such as tremors or a sudden shift in fluid properties

- Disruptions to the flow profile caused by surface roughness or imperfections

- Increased speeds or unfavorable flow conditions cause a change from laminar to turbulent flow.

Future Trends in Lamina’r Flow Research

To overcome these obstacles and uncover untapped opportunities, researchers are constantly examining lamina’r flow. Possible directions for the future of lamina’r flow studies include:

- Modern approaches to computer modeling and simulation

- The improvement of fluid dynamics through the creation of new materials and surface coatings

- Combining microfluidics and nanofluidics to regulate lamina’r flow with high accuracy

Conclusion

The interesting phenomena of lamina’r flow has many real-world applications in a wide range of disciplines. The advantages of efficiency, command, and lower contamination concerns that result from its streamlined and organized motion are obvious. Optimized designs and enhanced processes are possible via a deeper understanding of the concepts and elements driving laminar flow.

FAQs

Is lamina’r flow always desirable in fluid systems?

Some tasks, such as those involving mixing or heat transmission, are better served by a more turbulent flow than a lamina’r one.

How is lamina’r flow different from turbulent flow?

Smooth, parallel layers of fluid motion characterize lamina’r flow, while eddies and mixing throughout the fluid characterize turbulent flow.

Can lamina’r flow transition to turbulent flow?

Yes, lamina’r flow can change into turbulent flow at higher velocities or under adverse flow circumstances. The fluid’s characteristics and the shape of the channel both play a role in determining this tipping point.

What is the significance of the Reynolds number in lamina’r flow?

The Reynolds number is useful for establishing the flow regime by contrasting the impact of inertial and viscous forces. At low Reynolds numbers, where viscous forces predominate, lamina’r flow is observed.

How can lamina‘r flow be measured or visualized?

Flow visualization dyes or particles are examples of methods that can be used to see lamina’r flow. Lamina’r flow can also be quantified with the help of flow meters and pressure drop measurements.