I have followed the evolution of automotive systems closely, and switching 2nd automotive technology stands out as one of the most influential yet misunderstood shifts in modern vehicle engineering. This technology sits quietly behind dashboards, power modules, and control units, but it defines how efficiently energy moves inside a vehicle. When engineers talk about smarter cars, better fuel economy, or stable electric drivetrains, they often refer indirectly to advances in switching technology. I see it not as a single invention but as a layered progression that connects mechanical logic with digital intelligence. From traditional combustion vehicles to hybrid and fully electric platforms, switching 2nd automotive technology plays a decisive role in reliability, safety, and performance. Understanding it helps explain why modern vehicles behave differently from older ones and why future mobility depends so heavily on precise electronic control.

Understanding Switching Technology in Automotive Systems

Switching technology in automotive systems refers to the methods used to control electrical current flow between components. In early vehicles, switching was mostly mechanical, relying on relays and physical contacts. Over time, electronics replaced many of these elements with semiconductor based switches that operate faster and with greater precision. Switching 2nd automotive technology represents the second major wave of this transition, where intelligent electronic switches became integrated with sensors, microcontrollers, and software logic.

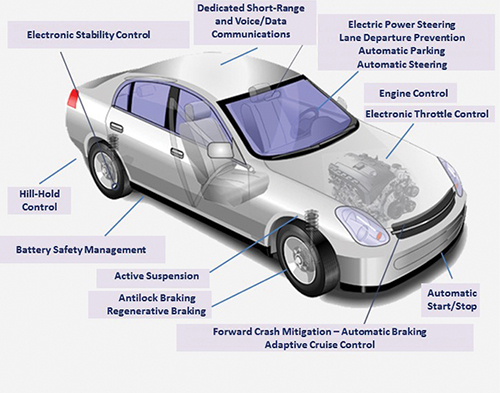

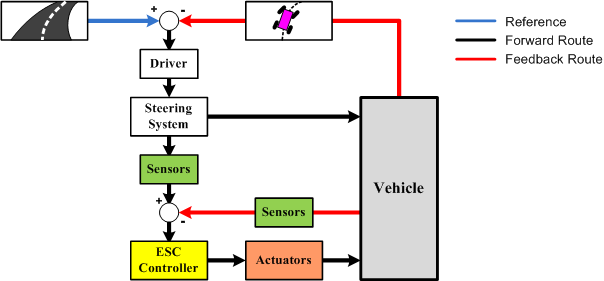

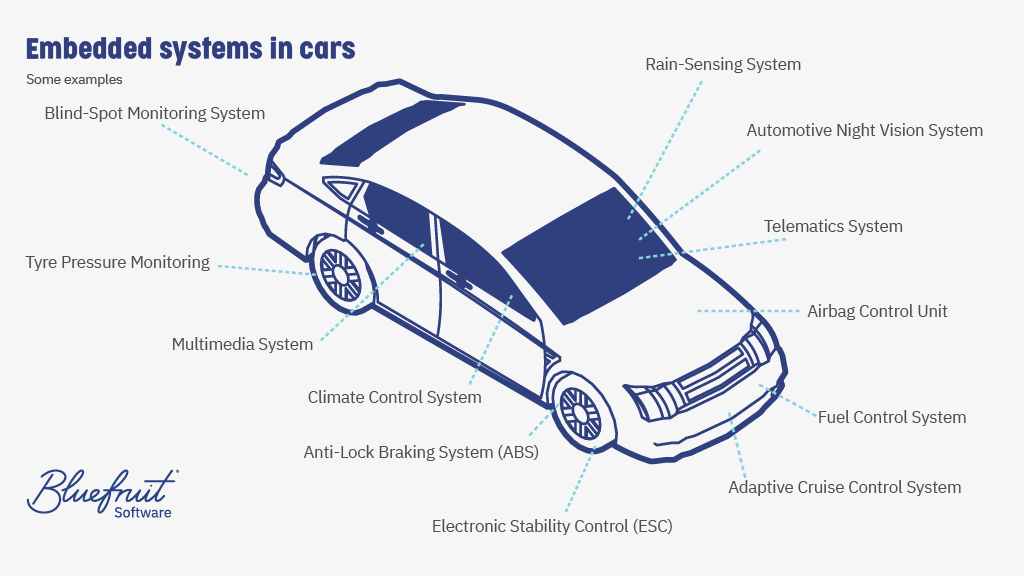

I observe that this shift allowed vehicles to respond dynamically to changing conditions. Instead of simple on and off states, systems now adjust current, voltage, and timing in real time. This capability supports complex functions such as adaptive transmission behavior, regenerative braking, and electronic stability control. The technology reduces energy losses and improves durability because components operate within optimized ranges rather than fixed limits.

Evolution From First Generation to Second Generation Switching

The first generation of automotive switching relied heavily on electromechanical devices. These systems were robust but limited in speed and flexibility. Contacts wore out, response times were slow, and integration with digital systems was minimal. Switching 2nd automotive technology emerged as electronics matured and vehicle architectures became more centralized.

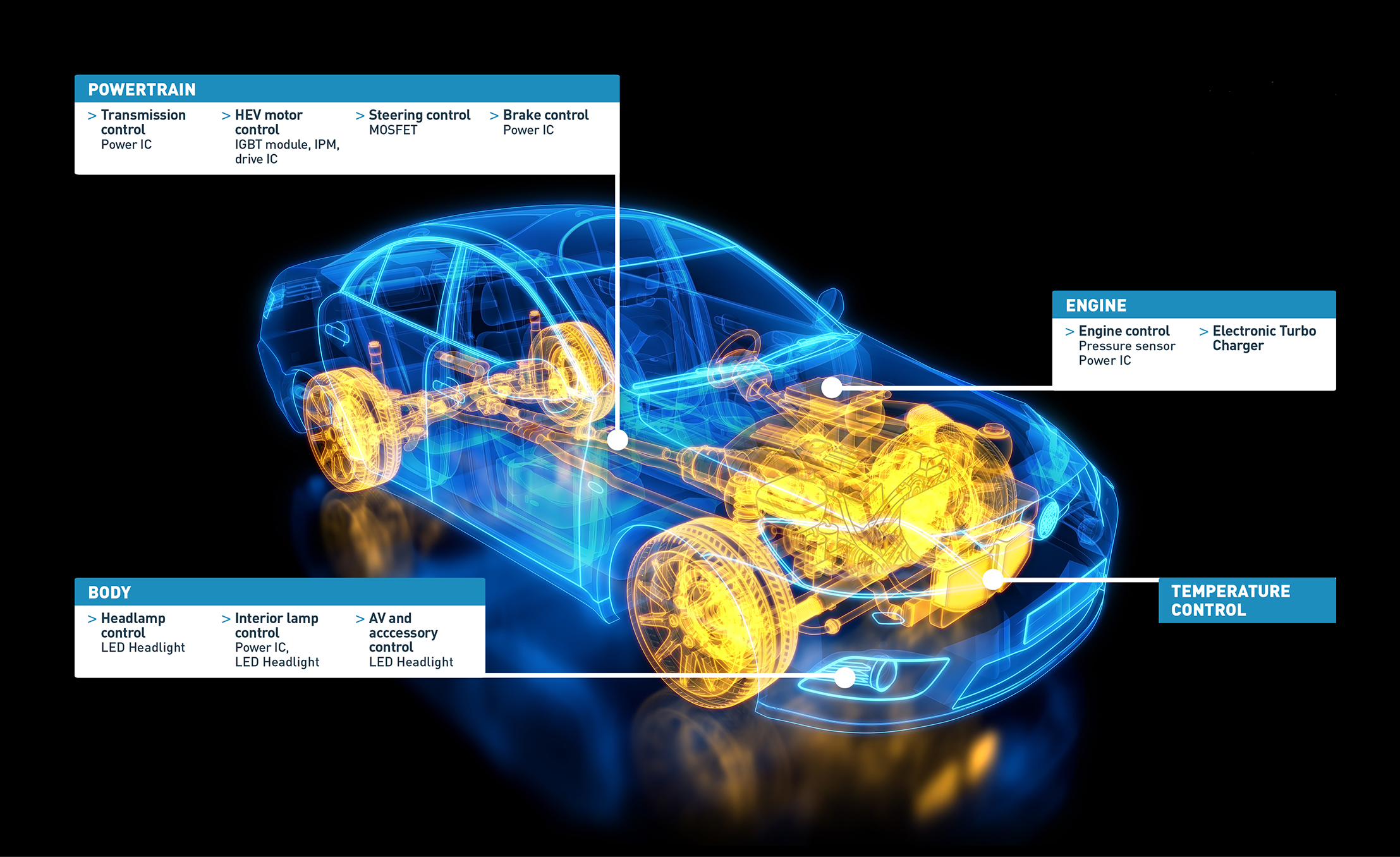

In this second phase, solid state switches such as MOSFETs and IGBTs replaced many mechanical components. Control logic moved into electronic control units, allowing one module to manage multiple functions. I find this evolution critical because it enabled scalability. A single design philosophy could be applied across different vehicle models with software adjustments rather than hardware redesigns. This shift laid the groundwork for modern modular vehicle platforms.

Core Components of Switching 2nd Automotive Technology

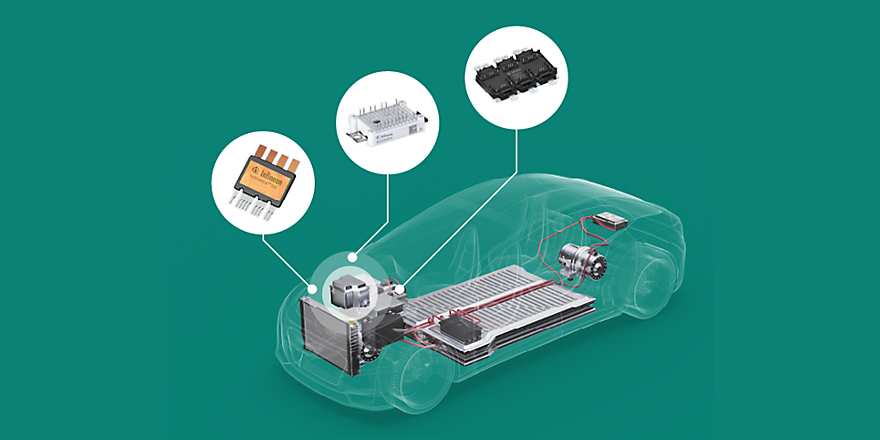

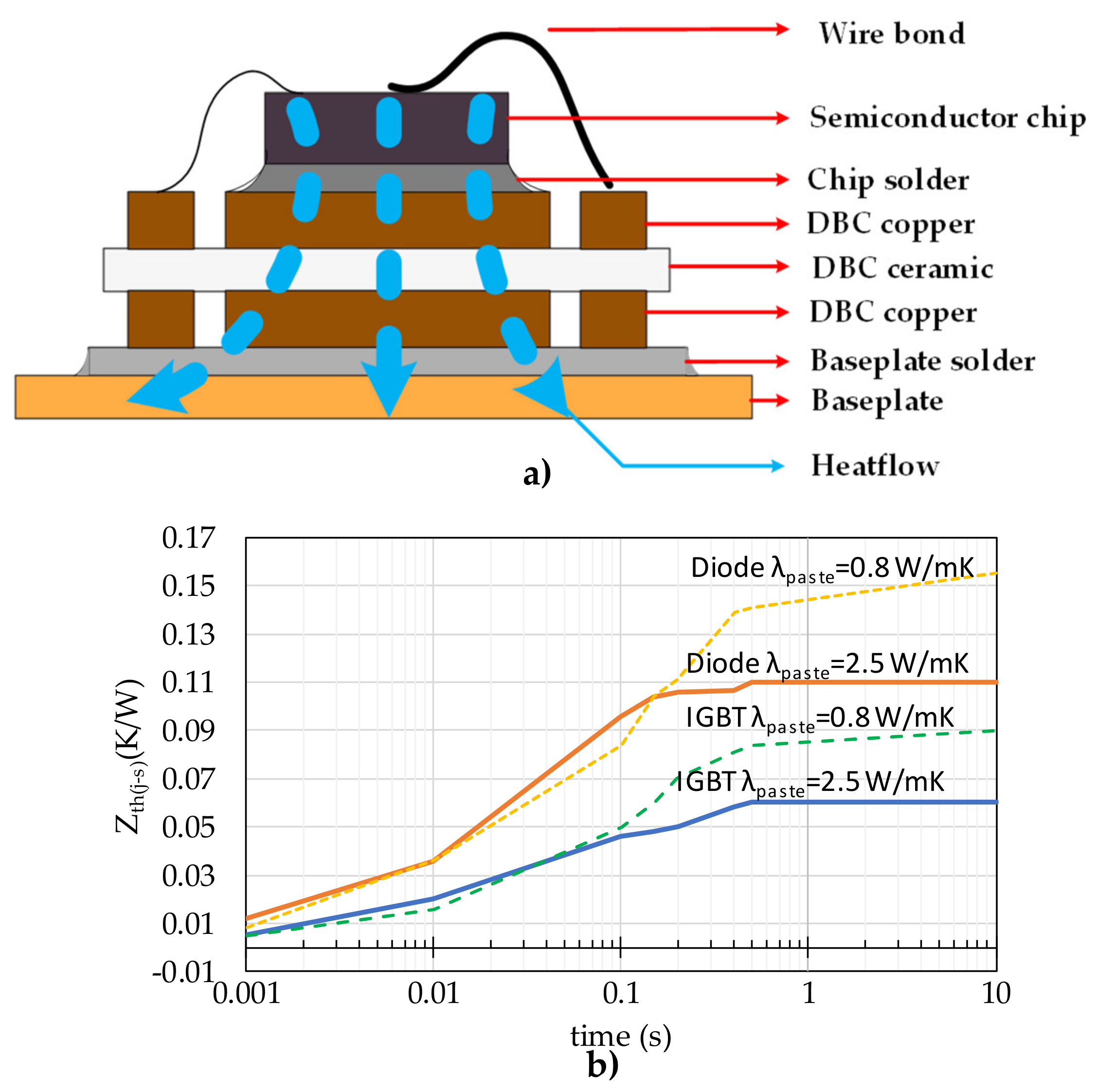

At the heart of switching 2nd automotive technology are power semiconductors, control processors, and protective circuits. Power semiconductors handle high currents while maintaining efficiency. Control processors interpret sensor data and decide how and when switching occurs. Protective elements guard against overheating, voltage spikes, and short circuits.

What stands out to me is the level of integration. These components no longer operate independently. They form tightly coupled systems where feedback loops continuously refine performance. For example, a power module in an electric vehicle adjusts switching frequency based on temperature and load, ensuring smooth operation under varying driving conditions. This intelligent coordination defines the second generation approach.

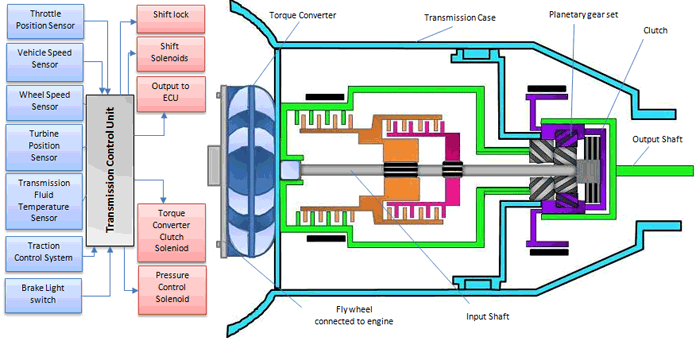

Role in Modern Transmission and Drivetrain Systems

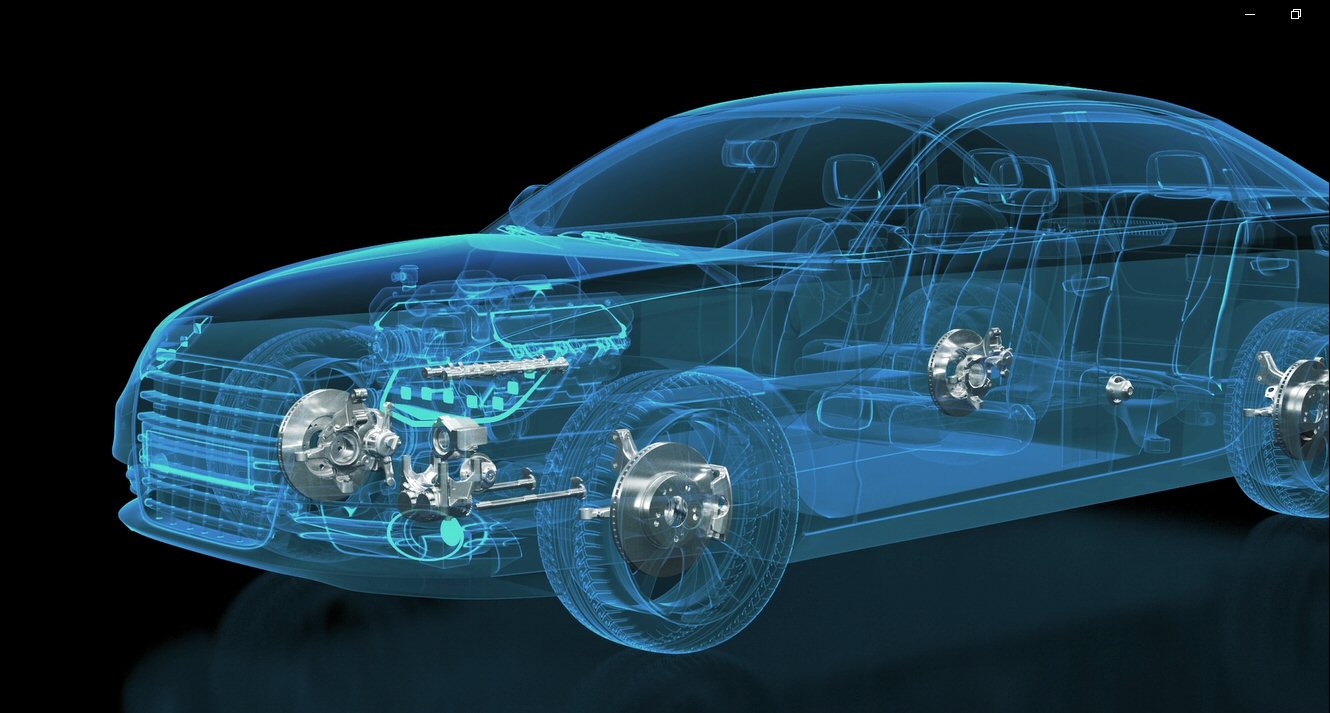

Switching 2nd automotive technology plays a central role in modern transmissions and drivetrains. Traditional automatic transmissions relied on hydraulic control with limited electronic oversight. Today, electronic switching governs solenoids, actuators, and motors that manage gear changes with precision.

I notice that this results in smoother shifts, reduced wear, and improved fuel efficiency. In electric drivetrains, switching technology becomes even more critical. Inverters convert battery power into controlled motor output through rapid electronic switching. The quality of this switching directly affects acceleration, noise levels, and energy consumption. Without advanced switching systems, modern drivetrains would struggle to meet performance and efficiency expectations.

Impact on Vehicle Safety and Stability Systems

Safety systems rely heavily on precise control, and switching 2nd automotive technology delivers that control. Anti lock braking, traction control, and electronic stability systems depend on rapid switching to modulate braking force and engine output. These actions occur within milliseconds and often without driver awareness.

From my perspective, the significance lies in predictability. Electronic switching ensures consistent responses across different road conditions. Mechanical systems alone could not achieve this level of responsiveness. The technology allows vehicles to maintain stability during sudden maneuvers, reducing accident risks and improving driver confidence.

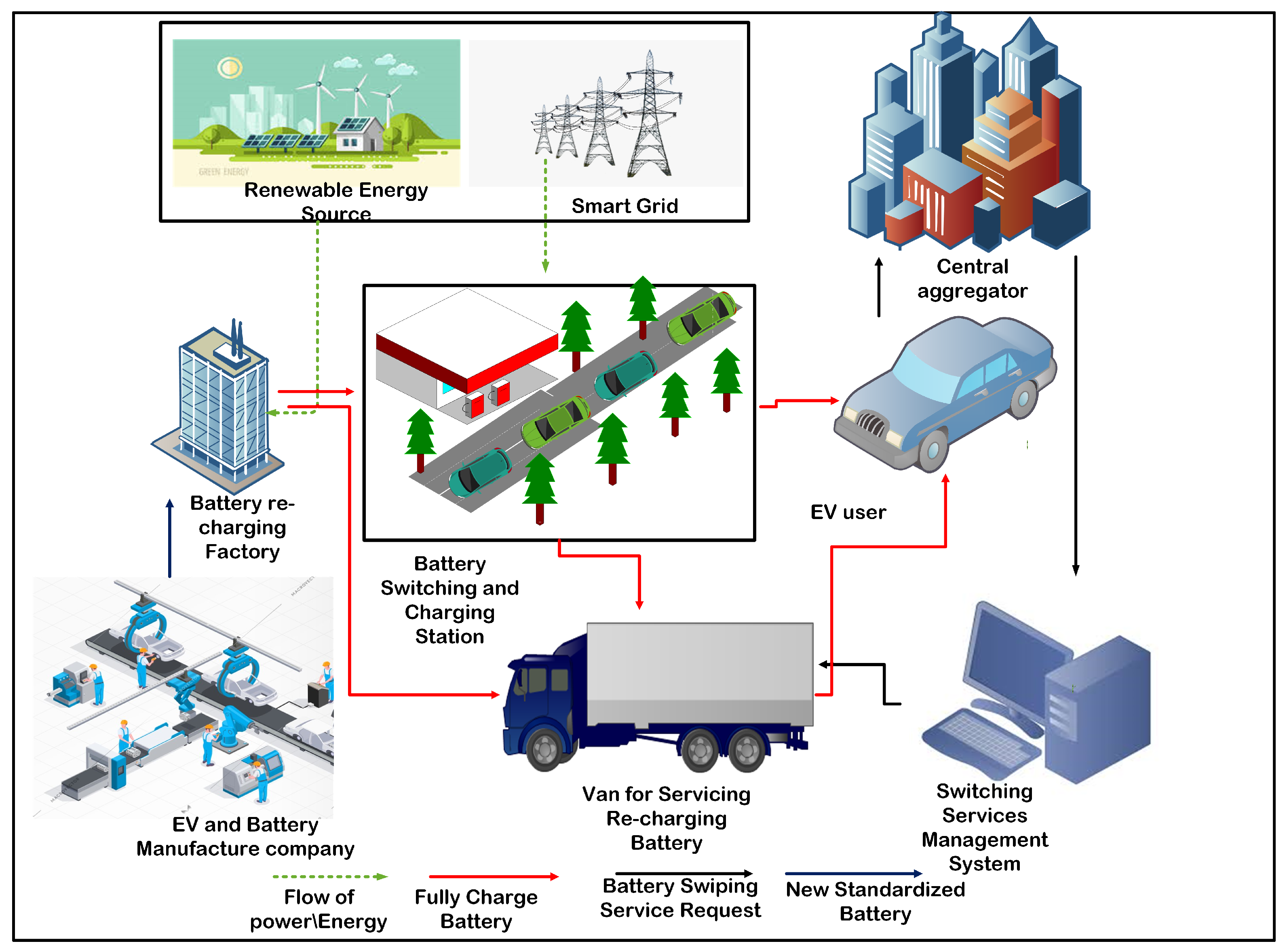

Integration With Hybrid and Electric Vehicles

Hybrid and electric vehicles showcase the full potential of switching 2nd automotive technology. These platforms depend on efficient energy conversion and distribution. Switching systems manage battery charging, motor control, and energy recovery during braking.

I find it remarkable how seamlessly these processes occur. Drivers experience smooth acceleration and quiet operation, yet behind the scenes, thousands of switching events happen every second. The technology balances performance with battery longevity by controlling current flow precisely. This balance is essential for making electric mobility practical and reliable.

Benefits for Efficiency and Energy Management

One of the strongest arguments for switching 2nd automotive technology is efficiency. By reducing energy losses during power conversion, vehicles consume less fuel or battery charge. Heat generation decreases, which extends component life and reduces cooling requirements.

I see energy management as a defining advantage. Modern vehicles monitor consumption patterns and adjust switching behavior accordingly. For instance, auxiliary systems may reduce power draw during high load situations. This intelligent prioritization improves overall efficiency without compromising functionality.

Reliability and Durability Improvements

Reliability is a constant concern in automotive design. Switching 2nd automotive technology addresses this by minimizing mechanical wear and optimizing thermal performance. Solid state components have no moving parts, which reduces failure rates.

In my analysis, durability improves because systems operate within controlled limits. Sensors detect anomalies early and adjust switching patterns to prevent damage. This proactive approach contrasts with older designs that reacted only after faults occurred. As a result, modern vehicles achieve longer service intervals and lower maintenance costs.

Challenges and Engineering Constraints

Despite its advantages, switching 2nd automotive technology presents challenges. High frequency switching can generate electromagnetic interference, requiring careful shielding and design. Thermal management remains critical, especially in compact vehicle architectures.

I also recognize cost and complexity as barriers. Advanced switching systems require skilled engineering and rigorous testing. Manufacturers must balance performance gains with affordability. These constraints shape how quickly new technologies reach mass markets.

Comparison of Traditional and Second Generation Switching

| Aspect | Traditional Switching | Switching 2nd Automotive Technology |

|---|---|---|

| Control method | Mechanical or basic electronic | Intelligent electronic with software |

| Response speed | Slow to moderate | Extremely fast |

| Efficiency | Lower | Higher |

| Maintenance | Frequent wear issues | Reduced wear |

| Integration | Limited | Highly integrated |

This comparison highlights why the second generation approach dominates modern designs. It aligns better with the demands of connected and electrified vehicles.

Software and Digital Control Layers

Software defines how switching 2nd automotive technology behaves. Control algorithms determine switching frequency, timing, and response to sensor input. Updates can refine performance without hardware changes.

I consider this adaptability essential. Vehicles evolve over their lifespan through software updates that improve efficiency or add features. Switching systems respond to these updates, demonstrating how deeply hardware and software now intertwine in automotive design.

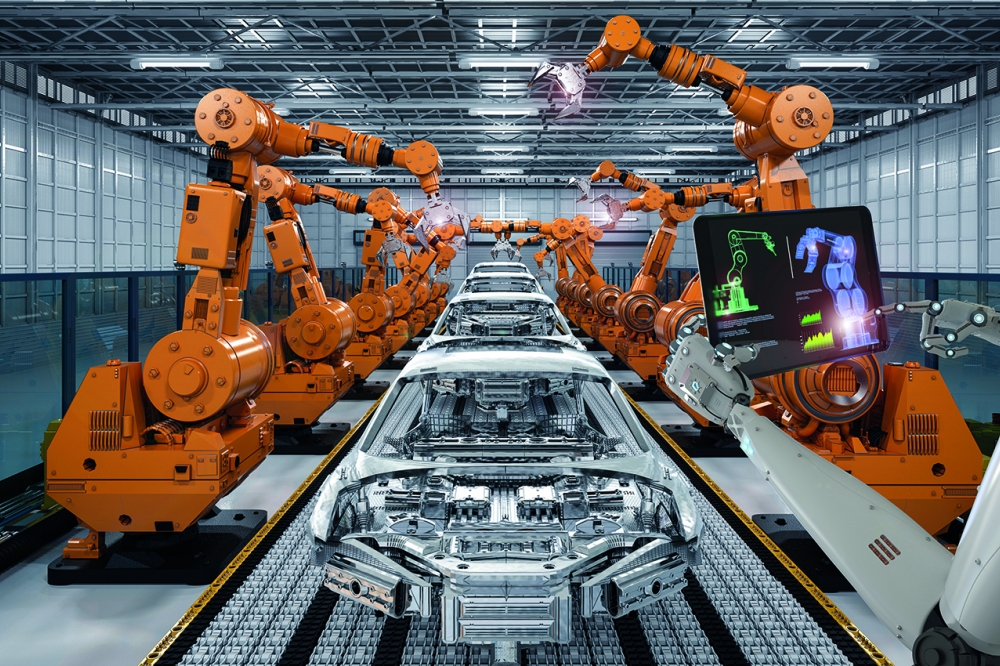

Manufacturing and Quality Assurance Considerations

Manufacturing switching systems requires precision. Components must meet strict tolerances to handle automotive environments. Quality assurance processes test for temperature extremes, vibration, and electrical stress.

From my experience observing production practices, consistency matters as much as innovation. Even small deviations can affect performance. Second generation switching technology pushes manufacturers toward more automated and monitored production methods.

Future Trends in Switching Automotive Technology

Looking ahead, switching 2nd automotive technology continues to evolve. Wide bandgap semiconductors promise higher efficiency and smaller designs. Integration with autonomous driving systems will demand even faster and more reliable switching.

I expect future vehicles to rely on unified power architectures where switching systems coordinate across the entire vehicle. This holistic approach will simplify design while enhancing performance.

Broader Impact on the Automotive Industry

The influence of switching 2nd automotive technology extends beyond individual vehicles. It shapes supply chains, workforce skills, and industry standards. Engineers increasingly focus on electronics and software alongside mechanical design.

In my view, this shift redefines what it means to build a car. Automotive engineering becomes a multidisciplinary effort where switching technology serves as a critical link between energy, intelligence, and motion.

Read: Showcamrips Explained: Piracy, Risks, and Digital Culture

Conclusion

I see switching 2nd automotive technology as a quiet revolution that underpins modern mobility. It enables efficiency, safety, and adaptability across vehicle platforms. While drivers may never think about it, their experience depends on countless precise switching events happening every moment. As vehicles continue to electrify and digitize, this technology will grow even more central. Understanding it offers insight into how cars have changed and why future transportation will rely on intelligent control rather than purely mechanical solutions.

Read: Tracqueur: Tracking Technologies, Uses, and Impacts

FAQs

What is switching 2nd automotive technology?

It refers to advanced electronic switching systems integrated with software and sensors to control power and functions in modern vehicles.

Why is this technology important for electric vehicles?

Electric vehicles rely on precise switching to manage battery power, motor control, and energy recovery efficiently.

Does it improve vehicle safety?

Yes, it enables fast and accurate control of braking, stability, and traction systems.

Is maintenance reduced with second generation switching?

Maintenance needs decrease because solid state components have fewer wear related failures.

Will future cars depend more on switching technology?

Yes, increasing electrification and automation will make advanced switching systems even more essential.