When precision matters most in mechanical work, a thread alignment tool becomes indispensable. This specialized device is designed to ensure that threaded fasteners, such as bolts and screws, align perfectly with their mating threads during assembly or repair. Misalignment can lead to damaged components, unsafe installations, and increased costs in maintenance or replacements. The thread alignment tool addresses these issues by guiding threads smoothly into place, preventing cross-threading, and ensuring a secure fit. Whether used in heavy machinery, automotive repairs, aerospace, or even smaller-scale DIY projects, its role cannot be overstated. This article explores the mechanics, benefits, applications, and modern advancements of thread alignment tools, while also comparing variations and providing insights for both professionals and enthusiasts. Readers seeking clarity on how these tools function, where they are applied, and why they are vital to industrial and household practices will find comprehensive information here. With practical explanations, real-world examples, and structured details, the discussion demonstrates how a simple device can safeguard complex operations.

What is a Thread Alignment Tool?

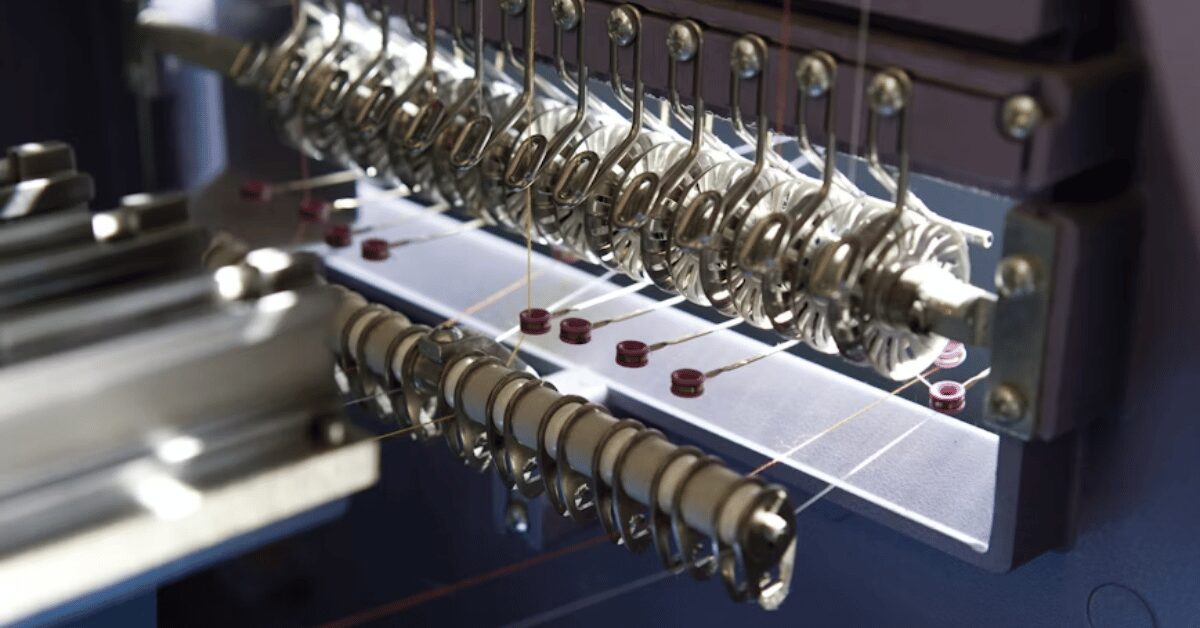

A thread alignment tool is a mechanical aid that ensures threaded components properly engage during fastening operations. Unlike standard taps or dies, which cut threads, these tools focus on guiding and correcting alignment without altering the material. They are particularly useful when working with delicate threads in metals, plastics, or composites where precision is essential. Typically made from durable alloys or hardened steel, the tool’s tapered design helps coax a bolt or stud into the correct thread path, reducing the chances of cross-threading. It may also serve as a diagnostic device to check for thread wear or minor defects before tightening. In workshops, engineers often keep various sizes of alignment tools to match industry-standard thread pitches and diameters. The evolution of these tools reflects a blend of traditional craftsmanship and modern engineering, offering both manual and automated versions depending on the scale of work.

Why Thread Alignment Matters in Modern Industries

Thread alignment is not a minor detail—it can determine the longevity, safety, and efficiency of machinery. A misaligned thread can compromise the structural integrity of an assembly, leading to part failure, leaks in fluid systems, or catastrophic breakdowns in load-bearing applications. For example, in the aerospace sector, even a minor cross-threaded fastener can lead to costly repairs and potential safety risks. Similarly, automotive engines rely heavily on threaded connections where improper engagement may result in oil leaks, overheating, or vibration issues. The manufacturing industry also emphasizes alignment because poor thread quality reduces efficiency during mass production. In medical equipment, thread alignment ensures precision fittings that must meet hygiene and safety standards. As industries grow more dependent on high-precision operations, tools that safeguard threading processes become more critical. Hence, the thread alignment tool is valued as a preventive measure rather than a corrective fix, embodying the engineering principle that prevention is always better than repair.

Types of Thread Alignment Tools

Thread alignment tools come in different forms, each tailored to specific applications. The most common type is the tapered guide tool, which resembles a smooth-ended fastener that eases into existing threads. Adjustable alignment tools allow mechanics to work across various diameters, offering versatility when thread sizes vary. There are also hydraulic or pneumatic-powered versions used in large-scale industrial settings, particularly when components are too heavy for manual alignment. In precision engineering, optical and digital alignment tools are used to measure and guide threading with laser accuracy. These advanced versions integrate with machine systems, providing feedback during assembly to reduce human error. Each type balances simplicity and sophistication, allowing both general users and specialists to benefit. While manual versions remain affordable and reliable, the automated models represent the technological future of alignment. Their widespread use highlights how even the smallest detail, like threading, deserves significant engineering attention.

Table 1: Types of Thread Alignment Tools and Their Applications

| Type of Tool | Description | Primary Application Area | Advantage |

|---|---|---|---|

| Tapered Manual Tool | Guides threads into place manually | Automotive repair, DIY projects | Affordable, easy to use |

| Adjustable Alignment Tool | Works on multiple thread diameters | Workshops, maintenance facilities | Versatility, saves space |

| Hydraulic/Pneumatic Tool | Uses pressure for large-scale alignment | Heavy machinery, industrial plants | Reduces manual effort |

| Digital/Optical Tool | Laser or camera-guided precision | Aerospace, medical engineering | High accuracy, reduces errors |

How Thread Alignment Tools Prevent Damage

The primary risk in any threading process is cross-threading, where the fastener enters at the wrong angle and damages the mating part. A thread alignment tool prevents this by introducing a guiding taper that naturally centers the fastener before it engages fully. By eliminating guesswork, the tool saves time and prevents costly replacements of stripped bolts or nuts. Moreover, alignment tools preserve the integrity of components made from softer materials like aluminum, brass, or plastic, where threads are more susceptible to wear. They also help in situations where visibility is limited, such as recessed or blind holes, where misalignment can easily occur. For industries handling expensive parts, such as aerospace or medical devices, the prevention of even a single cross-threaded fastener justifies the investment in these tools. As one mechanic aptly said, “The cost of a tool is always cheaper than the cost of a mistake.”

Materials and Manufacturing of Thread Alignment Tools

Thread alignment tools must endure repeated use under mechanical stress, which is why manufacturers typically choose hardened tool steels, alloy steels, or titanium blends. The tool surface often undergoes heat treatment or coating with protective finishes like black oxide to resist corrosion. Precision machining ensures the taper and diameter match the thread standards of bolts and nuts. Advanced designs may include ergonomic handles or quick-release features for user convenience. Some modern alignment tools even integrate with smart torque wrenches, allowing users to not only align threads but also ensure tightening accuracy in one process. Manufacturing processes balance mass production efficiency with strict quality control, as even small dimensional errors could compromise the tool’s effectiveness. Sustainability has also entered this space, with manufacturers experimenting with recycled steel and energy-efficient processes. The result is a blend of traditional durability with modern eco-conscious production.

Common Industries Using Thread Alignment Tools

Thread alignment tools find application in diverse industries. Automotive repair shops frequently use them when working with engine heads, transmissions, and suspension systems. Aerospace companies rely on alignment tools for precision fittings in aircraft structures, where even micro-level errors cannot be tolerated. Heavy machinery and construction equipment maintenance teams use large alignment tools to handle bolts in massive joints. In marine engineering, where rust and corrosion often affect threads, alignment tools help salvage and reuse critical fittings. The medical device sector applies smaller, high-precision alignment tools in equipment like surgical instruments or implants. Even in consumer applications, such as assembling furniture or bicycles, these tools provide value by preventing damage. Their versatility across industries underscores their universal importance. As one industrial engineer remarked, “Threads may be small, but they hold together the world’s biggest machines.”

Table 2: Key Industries and Use Cases of Thread Alignment Tools

| Industry | Typical Use Case | Benefits of Alignment Tool |

|---|---|---|

| Automotive | Engine bolts, transmission fasteners | Prevents cross-threading, saves time |

| Aerospace | Aircraft frame fittings, landing gear | Precision, compliance with safety codes |

| Heavy Machinery | Construction equipment joints | Handles large bolts, reduces strain |

| Marine Engineering | Corroded thread restoration | Extends life of fittings, prevents leaks |

| Medical Devices | Surgical instruments, implants | High precision, ensures reliability |

| Consumer Products | Furniture, bicycles, DIY projects | Protects delicate threads, easy assembly |

Modern Advancements in Thread Alignment Tools

Technological innovation has significantly transformed thread alignment tools. Today, advanced models use digital sensors that detect thread angle and alignment in real-time, guiding users with feedback indicators. Some systems integrate with augmented reality headsets, overlaying digital guides during assembly in aerospace or automotive production lines. Portable alignment kits now feature interchangeable heads, reducing the need for multiple separate tools. In industries prioritizing efficiency, alignment tools are connected to IoT platforms, tracking tool usage and wear for predictive maintenance. These advancements demonstrate a shift from simple corrective tools to intelligent systems that actively enhance workflow. The trajectory suggests that future alignment tools may fully automate threading, using robotic arms to align and fasten with minimal human involvement. This blend of mechanics, electronics, and data intelligence marks a new chapter for what was once a simple tapered device.

Best Practices for Using Thread Alignment Tools

To maximize the effectiveness of a thread alignment tool, users should follow best practices. First, selecting the correct size and type of tool is crucial; forcing the wrong tool can cause more harm than good. Cleanliness also matters, as debris in threads can obstruct alignment. Applying a light lubricant often eases engagement, especially with stubborn or corroded parts. Mechanics are advised to insert the alignment tool gently, allowing the taper to find its path without excessive force. Regular inspection of the tool itself ensures it remains accurate and free from wear. Storing tools in protective cases reduces corrosion and physical damage. Following these practices turns the tool into a reliable companion rather than a last-minute savior. As one craftsman noted, “Respect your tools, and they’ll respect your work.”

Training and Skill Development in Thread Alignment

Although the tool is simple to use, training enhances its effectiveness. Workshops and vocational programs often include modules on proper threading and alignment techniques. Trainees learn about thread standards such as metric and imperial measurements, ensuring they select the correct tool for each task. Practical exercises simulate common problems like stripped bolts or seized threads, teaching users how alignment tools can resolve them without further damage. Advanced training programs for aerospace or medical technicians emphasize precision and quality control, ensuring that alignment is not only mechanical but also documented for compliance. Even DIY enthusiasts benefit from video tutorials and hands-on practice. Building skill with alignment tools fosters confidence, reduces waste, and instills respect for detail-oriented work.

The Economics of Using Thread Alignment Tools

From an economic perspective, thread alignment tools save money by reducing rework, minimizing part replacements, and preventing downtime. In manufacturing plants, misaligned threads can halt entire production lines, costing thousands per hour. By integrating alignment tools, companies reduce defects and maintain efficiency. In automotive workshops, preventing damage to engine blocks or transmission housings avoids costly replacements. Even at the household level, a small investment in an alignment tool extends the life of furniture and appliances. The return on investment is clear: preventing a single costly error often outweighs the tool’s purchase price. Furthermore, industries adopting advanced digital alignment tools may find long-term gains through predictive maintenance and reduced warranty claims. The balance between cost and benefit firmly tilts in favor of alignment tools.

Environmental Impact and Sustainability

Thread alignment tools contribute indirectly to sustainability by extending the lifespan of threaded components and reducing material waste. When threads are properly aligned, fewer parts are scrapped due to damage. Reusing bolts and nuts, especially in industries like marine or construction, lessens resource consumption. Additionally, modern manufacturers are producing alignment tools with recycled materials and eco-friendly coatings. By promoting reuse and repair, these tools align with the global trend of sustainability in engineering practices. Their role in waste reduction highlights how even small devices contribute to larger environmental goals. As one sustainability advocate in manufacturing stated, “Every preserved thread is one less piece in the landfill.”

Future Outlook of Thread Alignment Tools

The future of thread alignment tools is likely to be shaped by automation, digital integration, and sustainability. We may soon see fully automated threading stations where alignment, fastening, and torque measurement occur simultaneously with robotic precision. Integration with digital twins and smart factories will allow alignment tools to provide live feedback, enhancing traceability in industries requiring stringent compliance. Portable consumer models may evolve into smart devices that connect with smartphones, guiding hobbyists in real-time through augmented reality. As additive manufacturing grows, alignment tools might adapt to new thread materials and hybrid designs. Their enduring relevance ensures that while the design may evolve, the underlying principle of protecting threads will remain timeless.

Conclusion

Thread alignment tools, though simple in concept, play an essential role across industries and everyday applications. They prevent cross-threading, reduce costly errors, extend component lifespan, and enhance safety. From manual tapered tools in automotive workshops to advanced digital systems in aerospace, their versatility underscores their universal value. Modern advancements have only increased their efficiency, integrating them into smart manufacturing and precision-driven environments. Economically, they save more than they cost, while environmentally, they promote sustainability through waste reduction. As industries advance and technologies evolve, the thread alignment tool will continue to adapt, blending tradition with innovation. In the words of one engineer, “It is not the size of the tool that matters, but the scale of problems it prevents.” For anyone handling threaded components, whether a professional or a DIY enthusiast, owning and understanding this tool remains a cornerstone of reliable mechanical practice.

FAQs

Q1: How does a thread alignment tool differ from a thread repair tool?

A thread alignment tool prevents cross-threading, while repair tools fix damaged threads. Alignment focuses on prevention, not correction.

Q2: Can thread alignment tools be used on both metric and imperial threads?

Yes, most alignment tools are available in metric and imperial sizes, and adjustable tools cover multiple diameters.

Q3: Do digital thread alignment tools require calibration?

Digital and optical tools may require periodic calibration to maintain accuracy, especially in aerospace and precision industries.

Q4: Are alignment tools effective for corroded or rusted threads?

Yes, with lubrication, alignment tools help restore engagement, but heavily corroded threads may still need repair.

Q5: What industries benefit most from advanced thread alignment tools?

Aerospace, automotive, and medical engineering benefit most due to their high precision demands and strict safety standards.