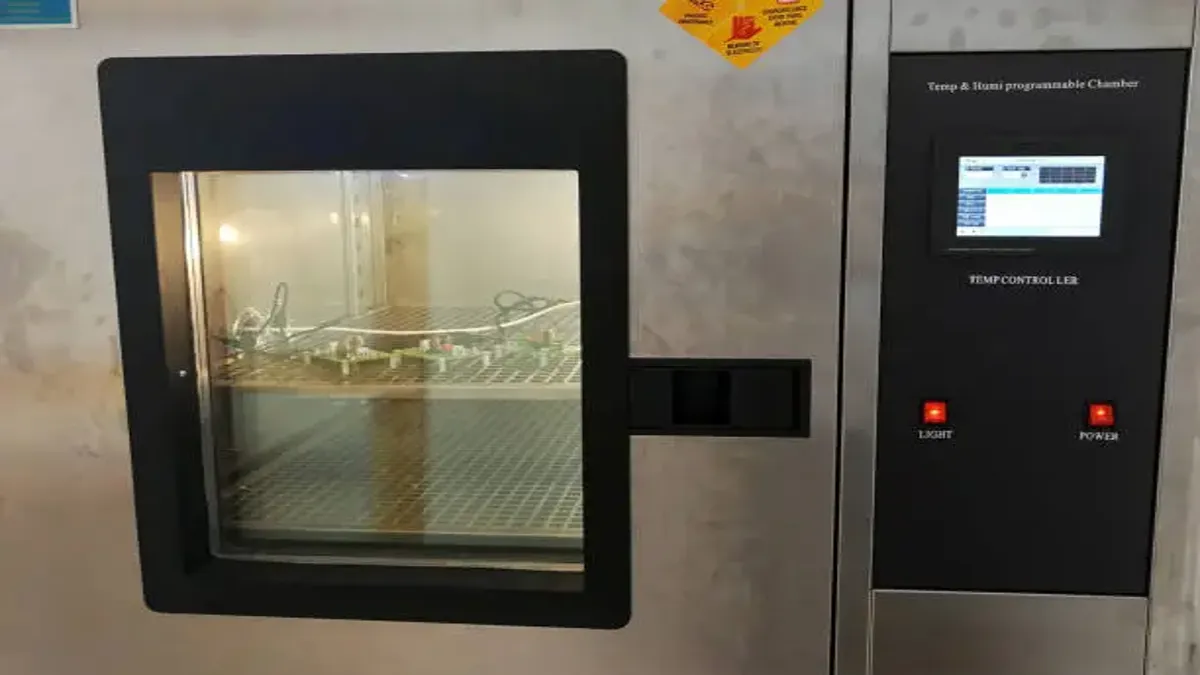

When you release a product to the market, you must ensure its quality and reliability. But what if it is constantly exposed to climatic influences? It means that the product needs to be tested for resistance to them. For this purpose, various installations are designed to simulate adverse natural factors. Today, we will discuss purchasing sand and dust test chambers.

Operation Principle of Sand and Dust Test Chambers

Many companies offer sand and dust test chambers for sale. To understand what is exactly right for you, it is worth understanding the operating principles of this testing device.

A powerful flow is created in the working volume of the sand and dust chamber, setting in motion the calibrated particles located in a special container. A powerful axial fan does this. The particles that settle on the surface of the test piece and the bottom of the chamber are displaced into a cone-shaped system for collecting settling dust. From here, it is fed back into the container.

This mode can last from one second to 99 hours, depending on the specified test parameters. After the set time has elapsed, the chamber automatically switches off. Testing is used to check the results of continuous or periodic dust exposure, monitor the degree of particle settling on the surface, and assess the effect on the applied coating.

The operator must perform the following actions before starting:

- Place the test sample on a stand or shelf inside the chamber.

- Let the test time and interval range according to the selected test method.

- Set the pump start time and its restart interval.

- Set the total start time and activate the process.

Thus, after completing the cycle, you will be able to assess the sample’s state and determine whether any improvements are needed.

Selection Criteria

Now, let’s discuss choosing a camera directly. Before contacting the seller, note three essential factors:

- Type of exposure. Consider the conditions in which your product will be used and determine the degree of exposure to sand and dust. It is the most important consideration, as products intended for use in the desert are tested differently from those designed for use in the city.

- Test duration. Consider how long you need to test the product. It can be tested from a few minutes to several days.

- Product size. The test sample must fit into the chamber. Therefore, it is essential to consider this factor in advance. A chamber that is too big or too small will be a waste of money.

Once you have decided on these basic parameters, you can proceed directly to the selection. At this stage, you will need to examine the technical characteristics of specific models. If you don’t understand something, don’t hesitate to ask a consultant for help. Most often, sellers are interested in finding the best solution for you.

Conclusion

Choosing a sand and dust test chamber is a responsible matter. You must understand exactly what type of test you need. Then the choice will not be a serious problem. The seller will assist you in selecting the best option tailored to your specific needs.